![]()

The Queen

The Queen

![]()

The Material

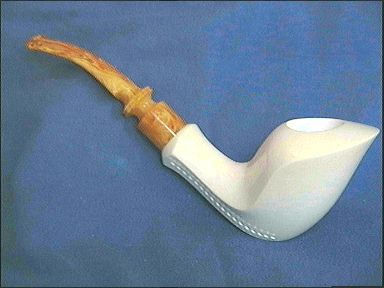

| It has been said that if briar is the King of pipes then meerschaum has to be the Queen of pipes. The material is named from the German meaning "sea-foam". In its purest state meerschaum is white as snow. It is very moist and almost pliable when it is first taken from the ground. It is made of Fossilized sea creatures, silica, carbonic acid, magnesia, and water. The deposits are found in the earth and must be mined. |

| The two most common places in the world for meerschaum to be found is in Africa and Turkey. African meerschaum is much more dense than Turkish meerschaum and does not have the same pure white color . Most of the pipes made from African meerschaum are colored in some way by the manufacturer. |

Turkish meerschaum is much more desirable as a medium for pipe making. It is very porous and easily carved. The smoke from Turkish meerschaum is much sweeter and drier than from any other meerschaum. It can no longer be exported from Turkey in a raw state. It must be carved before it can leave the country. There are several old world craft shops that have closed their doors because of this change in policy. |

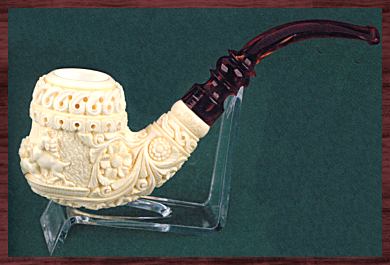

| The mining of meerschaum is very dangerous and does not pay very well. The mines have to go below the water level and they are damp and poorly lit. There have been some great artisans come from the carving process. Some of the best are Bolgi, Ismail Ozel, Husseyin Yanik, Munir Aydogu, and another called Sabri. The best known of these artists is Ismet Beckler. I have the honor to own a Sabri and it is absolutely beautiful. |

![]()

A History

| This story has been told so many times that it has now become fact. It is a good solid history and there is no way that it can be proven or disproved. You be the judge. |

| An Austrian Count named Andrassy obtained a large block of meerschaum. He was so impressed by the light weight and looks of the material that he commissioned a local pipemaker by the name of Karl Kowates to carve a pipe from the block. Mr. Kowates was not a foolish man. He found that the block was large enough to carve two pipes. So, in 1723, he carved those two pipes. One went to the Count and the other was kept and smoked by Mr. Kowates. |

A pipemaker in those days did not get rich or have much work. Mr. Kowates was also a shoemaker. He smoked this new pipe while working on those shoes and noticed that it was turning a nice shade of brown where he handled it with his fingers when he was smoking. After much thought, Mr. Kowates came tot he conclusion that it was a combination of the heat and the cobbler's wax that was on his fingers that caused the color of the pipe to change. He carefully waxed the entire pipe and soon had a pipe that was a beautiful shade of brown. Thus the legend of the first meerschaum goes. |

![]()

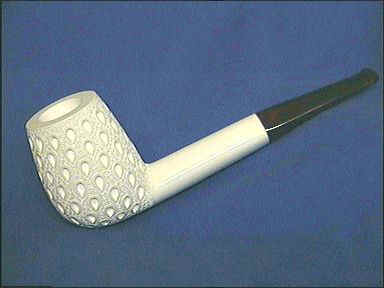

Coloring

| The last step in the making of a meerschaum pipe is to dip the entire pipe (minus the stem) into boiling bee's wax. This is done several times to make sure that the pipe is properly coated. There is a specially treated bee's wax that allows the pure white of the meerschaum to stay. Raw bee's was imparts a creamy coloration to the pipe. |

As the pipe is smoked, the colored juices from the tobacco and smoke are absorbed by the porous meerschaum. this goes through the pipe and is trapped by the outer coating of the wax. It then pervades the meerschaum and the coloring begins. That is why the thinner areas of the pipe color the fastest. The shank is usually the first part of the pipe to start turning color. It is wonderful to watch the slow progression of the color as it travels to other areas of the pipe.Just about any blend will cause the pipe to turn colors, but it seams that the heavier, darker blends tend to color the pipe a little faster. It is also said that it is better to smoke a meerschaum in a room where the air is not circulating very fast. This allows the exhaled smoke to stay near the pipe and some of that will color the wax on the outside of the bowl. I have known some who deliberately blow the smoke onto the outside of the bowl at different points in the hopes of making the color develop more quickly. |

![]()

Care And Cleaning

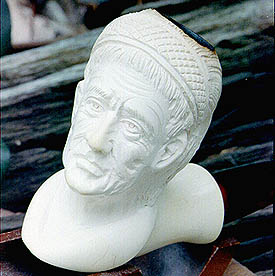

| There are only a few differences in the way one handles and cleans a meerschaum as opposed to a briar pipe. They are very important though. |

When smoking the meerschaum for the first 6 to 12 times, you should not touch the waxed areas of the pipe. Hold it by the stem while it is warm. That is so you will not disturb the wax coating on the pipe. some people say that the pipe should never be touched and the new school of thought is that it may be touched after these first smokes. The makers of these pipes say that the oils from the hands actually aid in the coloring of the pipe and handling it is desirable after the minimal break in period. I have done it both ways and find very little difference in the coloring. I like to touch my pipes and become a part of them when I smoke. You do it your way. |

The meerschaum pipe is not much more fragile than the briar. It has the same stress points as a briar. The big difference is the porosity of the material. The carving on the meerschaum pipe dictates a gentler and more careful handling of the pipe than does the briar. Smoking the meerschaum in cold weather is also more dangerous than smoking a briar. The expansion rate is greater in the meerschaum than in the briar and this sudden change in temperature on the outer surfaces of the meerschaum may produce cracking in the material. |

| Do not allow your meerschaum to sit in direct sunlight for any length of time. The sun will cause the outer surface of the pipe to yellow. this will not be the same tint as having the pipe color from smoking and may ruin your pipe for you. |

Do not allow the carbon cake to build on the inside of the bowl of your meerschaum the same way that you let the cake build on the inside of your briars. the expansion and contraction rate between the two materials is too great. This may lead to the bowl of the pipe cracking. I use a very fine grade of sand paper either rolled up or wrapped around a small piece of dow rod to keep the cake out of the meerschaum bowls. Be very careful to take only the cake and not the meerschaum out of the inside of the bowl. |

Do not clean the inside of the bowl or shank with cleaning fluids of any kind. Do not let these cleaning fluids touch the outside of the pipe either. This will ruin the coloring properties of the pipe. You may clean the stem the same way that you clean the stem on your briar only with less fluid so it will not run into the shank airhole. The stem should only be removed from a meerschaum when it is absolutely necessary to do so. The meerschaum is eroded each time you remove the stem and before long it will not seat properly to the pipe. The stem may also be buffed and polished the same as any other stem, but be very careful when buffing around the area where the stem meets the shank. |

| The antiqueing compound that is sold in the little tubes is not very good for the pipe. If it is applied unevenly, it will give an uneven color to the pipe as it is smoked. The pipe will color just fine if left alone and cared for properly. I tried using this stuff on one of my cheaper meerschaums and the results were less than desirable. |

![]()

Conclusion

| There you have it folks. As much as I know about the meerschaum pipe. I hope this has helped in some small way to further your enjoyment of the wonderful pipe. Long live the Queen! |

Here is another chance for you to leave feedback for me. I would like to hear from you. |

![]()

![]()