The Makings of a Guitar Pick

Picks- Funny little piece of plastic that nobody takes seriously, overshadowed by performer & instrument. Forever faithful, like a loyal dog. But Picks are very important part of playing, They are where the tone comes from. Imagine each pick as a work of art.Plectrums should be 40 to 60 Millicent in length and 1 millimeter thick. Flexibility could then be controlled by holding the pick nearer or farther away from the tip.

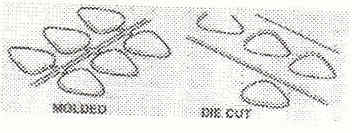

Picks are made in 2 ways injection molds or die cutting.

|

Injection Molding

Molded picks are formed by melting plastic into liquid form & Forcing it into molds of desired picks. Molding produces a material where the fibers are arranged in random matrix. Unless processed further the surface of a molded pick is shiny and smooth. (Celluloid cannot be molded)

Extruded/Die cut

Often plastics are forced into sheets or strips. From these sheets or strips knife sharp dies are used to stamp out the pick shape. The next process is the rough pick is sent into rock polishing- like tumblers to smooth & round the edges. The fiber in this method runs in 1 direction. This is believed to add stiffness & durability to the pick.

Delrin can be either injected or die cut. Nylon is the most popular on the molded method. Injection molded picks are often left with the natural shiny surface but also can be tumbled to produce a satin finish.

Guitar picks of the past were made from natural material, examples of these different materials are listed below!

1) Stone Mother of Pearl

2) Wood Leather

3) Bone Metal

4) Ivory Horns (animal)

5) Clamshell Tortoise Shell

Guitar Picks of today are made some of the following materials:

1) Celluloid

2) Delrin

3) Nylon

4) Carbon fiber plastics

5) Ceramic plastics

6) Thermoplastic

7) Acetyl polymer

8) Composite and laminated plastic

Most pick that are used today are made from nylon and thermoplastic material. The preferred material it is more flexible and durable then other materials.

Did you know that it takes at least 3 days to make a celluloid pick or any pick manufactured from sheet plastic. The plastic comes in various gauge sheets about 2’x5’ it is then slit into strips and punched out into a variety of shapes and then it is tumbled in at least 3 different mixtures to de-burr it, smooth it, polish it. Then it gets sorted & a logo or name printed on it then counted and bagged, and off it goes to a store or Kiss show anywhere in the world.