This is a 1967 Chevelle Malibu that I bought during my Senior

year in highschool. Yeah, I know, the paint is shot, its got some

rust, the fender is dented, etc, etc. But those wheels and tires

aren't too bad...

This is a 1967 Chevelle Malibu that I bought during my Senior

year in highschool. Yeah, I know, the paint is shot, its got some

rust, the fender is dented, etc, etc. But those wheels and tires

aren't too bad...

Well, looking back, I suppose it's only natrual that I would grow up to have at least a passing interest in electricity and electronics. Judging from my still somewhat vivid memory of me (three years old at the time) sticking my mother's car keys into an electrical outlet at the doctors office. (I seem to remember thinking that the little vertical slots looked like key slots and I was curious to see what was behind the little locked door!)

Throughout childhood, I had accumulated no less than a dozen of those "101 projects with electricity" kits from Radio Shack. I put in countless hours wiring circuits, winding coils, checking lights, etc., etc. and more or less most of the projects worked. That's not to say I haven't smoked my fair share of transformers, LED's, IC's, resistors, and a few capacitors to boot.

After graduating from college in December of 1995, with a Bachelor of Science Degree in Chemistry and minors in Manufacturing Technology and Plastics Technology, I began working for a small research and testing lab in southern Missouri. My main duty was performing Metallurgical Failure analysis along with chemical and mechanical testing of metals and other materials. Being such a small lab, word of my interest in electronics spread and I soon found my self doing the electronics testing as well. This involved such things as battery and lightbulb lifetime testing, lightbulb luminance studies, and computerized data aquisition.

But

in February 1998, I decided it was time to move on--That is when I took

my current job at a research and testing lab in Kansas. So, here

I am. My job description has somewhat narrowed in focus, but I still

have plenty of time to pursue my interests away from work.

Some Projects over the Years

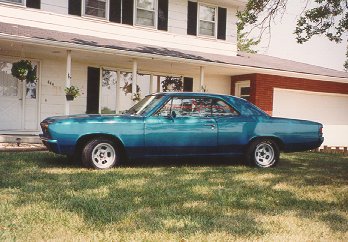

This is a 1967 Chevelle Malibu that I bought during my Senior

year in highschool. Yeah, I know, the paint is shot, its got some

rust, the fender is dented, etc, etc. But those wheels and tires

aren't too bad...

This is a 1967 Chevelle Malibu that I bought during my Senior

year in highschool. Yeah, I know, the paint is shot, its got some

rust, the fender is dented, etc, etc. But those wheels and tires

aren't too bad...

This

is the end result after about a year of blood, sweat and tears. Luckily,

the engine and transmission were in great shape when I bought the car.

Most of the work I did was body work, paint, and interior. The old Chevelle

is gone, but I found a nice Corvette to satisfy the "need for speed"!

This

is the end result after about a year of blood, sweat and tears. Luckily,

the engine and transmission were in great shape when I bought the car.

Most of the work I did was body work, paint, and interior. The old Chevelle

is gone, but I found a nice Corvette to satisfy the "need for speed"!

1967 Chevell Malubu

1967 Chevell Malubu

Engine:

283 cu in V-8, bored .030 over

flat tappet cam .491" lift, 283* duration

single Holley 600 cfm carb

Transmission: Turbo-Hydramatic 350

Interior:

Dove gray vinyl w/ raised accents

Power windows, locks, brakes, and steering

Paint:

1992 Aqua-metallic monochrome

Tires:

Pirelli P205 60 R14 front

BF Goodrich P255 60 R14 rear

This is a little demon I built back in 1995. I found

this old go-cart with a blown 3 HP Briggs & Straton engine and decided

it would be a perfect candidate for something a little bigger. If

you squint and look closely, you can just see the four orange spark plug

wires sprouting from behind the seat! They supply the 350cc 4-cylinder

Honda with ignition power. The 'lil Honda also sports electric start,

quad carburators and a 5 speed tranny. The designed gear ratios should

have put the top speed at about 120 MPH @ 5,000 RPM in fifth gear. (YIKES!!)

Unfortunately at about 50 MPH the little tires would stand up off of the

rim and rub the brake pads. I had planned to use a disk brake, but

the disk had a larger diameter than the tires!

This is a little demon I built back in 1995. I found

this old go-cart with a blown 3 HP Briggs & Straton engine and decided

it would be a perfect candidate for something a little bigger. If

you squint and look closely, you can just see the four orange spark plug

wires sprouting from behind the seat! They supply the 350cc 4-cylinder

Honda with ignition power. The 'lil Honda also sports electric start,

quad carburators and a 5 speed tranny. The designed gear ratios should

have put the top speed at about 120 MPH @ 5,000 RPM in fifth gear. (YIKES!!)

Unfortunately at about 50 MPH the little tires would stand up off of the

rim and rub the brake pads. I had planned to use a disk brake, but

the disk had a larger diameter than the tires!

This

is a 20 position heated extraction station for removing cyanide from soil

samples. The idea is to dissolve the soil in an acidic mixture (the

purple tubes at the back) which turns the cyanide compounds into HCN -

hydrogen cyanide gas. The gas then flows to the tubes in front (clear

liquid) and is turned into NaCN - sodium cyanide (solid). The setup

uses a couple of 555 Timers, full solid state switching, 10 - 400watt heaters

and can run in manual or automatic mode.

This

is a 20 position heated extraction station for removing cyanide from soil

samples. The idea is to dissolve the soil in an acidic mixture (the

purple tubes at the back) which turns the cyanide compounds into HCN -

hydrogen cyanide gas. The gas then flows to the tubes in front (clear

liquid) and is turned into NaCN - sodium cyanide (solid). The setup

uses a couple of 555 Timers, full solid state switching, 10 - 400watt heaters

and can run in manual or automatic mode.

Another

project (sorry, no pix) used the shop arc welder and some 1/2" diameter

tungsten electrodes to melt metal shavings into solid slugs so we could

do chemical analysis on the slug. The "remelting furnace" used 660

amps at 40 volts (26,400 watts) to melt the metal in a water cooled copper

crucible under an inert atmosphere of argon. This used mostly mechanical

relays, and motorized timers and had a fully automatic 5 step process.