When Henry Ford introduced the Flathead V-8 in 1932, it meant more power to hot rodders. His first flathead was the 21 - stud, 221 cid. 65hp engine. While this may not seem like much now, remember that in the 30's and 40's they didn't have all the knowledge of engines that we have now. This was unexplored territory, prettymuch.

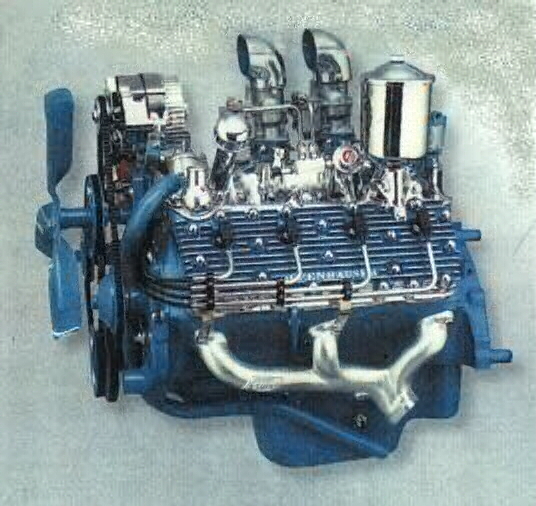

While that's a fine excuse for back then, it doesn't work today. You need horsepower and reliiability to be able to compete with GM and Mopar powered rods. So we need to change some stuff. First, the intake ports for flatheads were very restrictive, not letting the engine breathe well. This can be solved by porting and releiving the engine. This is simply grinding away all unneccessary metal. Another option is to stroke (increase the distance that the piston travels) the engine, thus increasing cubic inch displacement. Increasing compression with reproduction heads, overboring the engine, and adding carburetors are also among the changes you can make to a flathead. Of these, the easiest change is probably adding more carbs.

The way a flathead intake manifold is set up, the two cylinders in the front and two in the rear of the engine ran lean (not enough fuel), and the four center cylinders ran rich (too much fuel). This can be solved today by adding a second carb (and a third if you plan on racing). Four carbs is not recomended, although there were quad - carb intakes used on the original hot rods. Intakes and carbs for this application can be found at many rod shops and in magazines. Overboring is a relatively easy way to increase cubic inch displacement, but don't over do it, or you'll run into the coolant system and cracked blocks.

Exhaust systems for these engines were also a problem, as the two middle cylinders on each side of the engine shared an exhaust port. These two cylinders sharing one exhaust port restricted the speed at which the exhaust gasses could exit the engine, backing up the rest of the exhaust to some extent. People have experimented with various methods of fixing this problem. Some people have tried splitting the port with a piece of metal, but this takes up a lot of room, so it's not worth the tradeoff. Another option is to make another port, but unless you enjoy headaches and are very experienced at machining, it isn't recommended.

For more information (and more detailed, too), go to Hot Rod the Flathead.