Assignments

Assignments

Assignments

Assignments

Introduction

In the strict sense, ferrocement can hardly be considered a sustainable product. The combination of the two main materials are derived from two energy intensive and polluting processes: steel and cement manufacture.

Despite this drawback, ferrocement uses less cement than in any other concrete application and the calculated energy consumption for ferrocement is extremely favourable in comparison with traditional brick and cement products.

The use of ferrocement technology for shelter applications in combination with mud technology is increasingly gaining acceptance and is definitely more economical than concrete roofs.

Ferrocement is a type of thin-wall concrete commonly constructed out of cement mortar, reinforced with closely spaced layers of continuous and relatively small diameter mesh. The mesh may be metallic or made of other suitable materials. Ferrocement is considered to be an extension of reinforced concrete technology. The uniform distribution of the reinforcement in the resulting composite, its different material performance, strength behaviour and potential applications create the distinction between it and conventional reinforced concrete, enabling it to be classified as a separate material. Compared to RCC its main advantages are that it is light weight (less building materials, lighter supporting structure needed, prefab elements easier to handle); it has a higher ration of labour/building material; it is normally water-proof (if properly done) and almost any shape is possible.

Ferrocement possesses a degree of toughness, ductility, durability, strength and crack resistance that is considerably greater than that found in other forms of concrete construction. These properties are achieved in structures with a thickness generally less than 25 mm, a dimension that is nearly unthinkable in other forms of concrete construction, and a clear improvement over conventional reinforced concrete. Surprisingly good performance can be achieved in ferrocement with almost primitive field conditions and it does not necessarily require highly skilled practitioners. One can call it a high technology material, yet its production in terms of required labour skills and lack of sophistication of its constituent parts, could be viewed as a low technology.

Ferrocement has gained widespread use and acceptance, particularly in developing countries and has already attained worldwide popularity in almost all kinds of applications: marine, housing, water resources and sanitation, grain and water storage, biogas structures and for repair and strengthening of structures. Widespread use of ferrocement is evident in countries like China, USSR, India, Cuba and South East Asia.

There are several reasons for its widespread use. It can be fabricated into almost any shape, the skill needed for its construction can easily be acquired, heavy plant and machinery is not required and it is easy to repair.

Ferrocement use in Auroville

Auroville has been experimenting and using ferrocement technology since the 70's. The start was definitely not a success story, rather a trial and error situation where Auroville residents engaged in the construction of ferrocement buildings and elements, often without understanding or applying the basic principles of the technology. This was not altogether surprising since information and data on ferrocement was nearly non-existent during that period. The 80's brought some change. A more systematic and professional approach was applied when people with the necessary technical background joined the community and became involved in the technology. Contact was established with an international body which coordinates and promotes ferrocement technology on a global scale making latest research and developments in this field available. The result was that ferrocement applications in Auroville started to grow at a fast pace. Since that period Auroville has gained considerable experience of low-cost applications of ferrocement. The following are ferrocement milestones in Auroville:

The sculpture at the entrance of Aureka, the steel workshop.

1> The Auromodele roofs.

2>The Dana community with the first roof-channel house and wall-panel and also the first prefabricated work shed.

3> CSR building and work sheds.

4> Prefabricated ferrocement biogas plants.

5> Pitanga hall with compressed earth blocks and an 8 m. span roof channel for the yoga hall.

6> The overhead water tank for the school in Transition built on three columns.

7> The gymnasium dome for children in Certitude.

8> The diverse ferrocement roof sections situated all over Auroville. Today, we can say that almost every building built in Auroville uses ferrocement technology in one or the other way.

The major prefabricated products are:

Roofing elements.

Various shapes have been tested successfully, but till now the most commonly used one is ferrocement channels 3/4" thick. These are longitudinal sections of a cylinder (72 cm wide). Lengths of up to 6 meters are cast on the ground and require only a simple mould made of mud covered with cement plaster. Other components are a layer of chicken mesh (1/2", 22g.); longitudinal steel reinforcement, 2 rods 10mm, 1 rod 8mm; no transversal steel reinforcement; mortar of 1 cement/2 sand; curing of 2 days after casting the channels are demoulded and turned over; mini mud dams are simply made at both ends so that the channels may be filled with water. Width: 75cm. Span: 3-5 meters depending on reinforcement and load. For a 5m span, first mini crack appears with a load of 300kg/m2.

The channels are joined in-situ by linking the chicken mesh that sticks out on the side of each channel with another 10cm wide strip of chicken mesh. A mortar with small pebbles is then used (proportions: 1/2/3). A 5% slope may be given to the channels; they may also be laid flat if one wants to use them as a terrace or build above them. If such is the case, they are covered with a layer of bricks jellies lime mortar, and covered with a cement plaster.

Advantages over RCC roofs (in a village situation) are that they require no scaffolding, shuttering, concrete mixer or vibrator; and the materials are less costly. Instead of having to cast the roof in one day, which requires a lot of labour, channels can be made one by one at the site; they provide good insulation if brick jelly terracing is done and they do not require additional water proofing (if properly made).

Wall panels - 1"

These are used as walls in-between RCC columns and are supported by them; thus eliminating the need of foundation for the walls.

Design and cost varies with the size and spacing of the RCC columns. For a spacing of 3 meters, the approximate cost is: Rs.100/m2

Panels for shelving 3/4" to 1"

Tor steel is included in the reinforcement. Reinforcement and cost depend upon the load and span.

Thick panels: doors and shutters 1/2"

These do not need a mould, a simple (flat) concrete platform is enough. Only four layers of chicken mesh (1/2", 20g.), no other reinforcement needed. Mortar: 1 cement/1 sand. Curing: cover with wet sand. Maximum size: 2.5m x 1.5m Cost price: Rs 150/m2.

This Auroville innovation has a tremendous potential as its advantages over other doors are enormous: it is extremely cheap; strong, durable, fireproof, water & termite resistant; saves trees; its components are available everywhere; the manufacturing process is very readily acquired even by non-skilled labour and no investment is needed (if a platform is available).

Louvers

Several designs have been tried.

Water tanks

CSR manufactures various sizes of cylindrical water tanks with a capacity of 5,000 up to 7,500 litres at a cost of Rs 0.40/litre (this price includes only material and labour; installation cost is additional).

Latrines

Low-cost prefabricated ferrocement latrines with double leach-pits are manufactured. The idea is to manufacture everything (including foundation and leach-pit in the workshop) and assemble them on site again without any cement. Till now we are only making the cabin (cylindrical walls + door + roof); the rest will follow soon. The cost of the cabin is Rs. 2,500.

Other ferrocement applications.

Low-cost shuttering to avoid costly shuttering in case of complex shapes. Sun shades, covers, sinks, and water spouts, Domes of 3.5 m. diameter, Biogas plants (2, 3, and 4 cum.). Bath tubs and all sorts of decorative elements, including sculptures.

Furthermore, ferrocement is also extensively used as an in-situ technique for houses, store rooms, work sheds, etc.

Ferro cement triangles and portholes

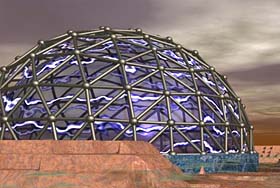

The present solution for the skin is to put ferro-cement triangles, each containing a `porthole', on top of the present skinstructure. Round ceramic tiles of 24 mm diameter will decorate the outside of the ferro-cement triangles. Ferro-cement, cast in situ, will also be used for the inside with a white finish. In order not to see the back of the disks from the inside of the Matrimandir through the portholes, it is proposed to use a special type of translucent glass. The result will be a luminous play of light on the entire inside surface the Matrimandir.

An Introduction to Geodesic Domes

Throughout recorded history man experimented with designs and materials towards the goal of doing more with less. No man in recent history has done more to advance this goal than R. Buckminster Fuller; philosopher, mathematician, engineer, historian, poet and inventor of the geodesic dome. Although the world took little notice in 1951 when Mr. Fuller first applied for patents on geodesic domes, today geodesic domes are recognized as the most efficient building system known to man. Adapting the dome to the single family, wood frame dwelling unit has, until recently, been inhibited by a general lack of technical design information, standardized dome building components and experienced dome home builders. With the recent widespread manufacturing of standardized "dome kits" and the dome home builder/distributor networks that have been established nationwide, dome home construction is now a practical reality almost anywhere in the U.S. or Canada.

The Birth of The Geodesic Dome

Although Buckminster Fuller invariably maintained that he was a comprehensivist who was interested in almost everything, his life and work were dominated by a single issue: shelter and housing. Even as a young boy in the early 1900s, Fuller--who preferred to be called Bucky--was constructing rudimentary structures and inventing better "environment controlling artifacts."

Buckminster Fuller invented the Geodesic Dome in the late 1940s to demonstrate some ideas about housing and ``energetic-synergetic geometry'' which he had developed during WWII. This invention built on his two decade old quest to improve the housing of humanity. It represents a brilliant demonstration of his synergetics principles; and in the right circumstances it could solve some of the pressing housing problems of today (this housing crisis Fuller predicted back in 1927).

The practical culmination of his quest to employ modern assembly-line manufacturing techniques and the best man-made materials in producing inexpensive, elegant housing came toward the end of World War II. In 1953, Fuller and his geodesic dome were elevated to international prominence when the first conspicuous commercial geodesic dome was produced known as the Ford Dome

Geodesic Domes

A Geodesic Dome is a type of structure shaped like a piece of a sphere or a ball. This structure is comprised of a complex network of triangles that form a roughly spherical surface. The more complex the network of triangles, the more closely the dome approximates the shape of a true sphere.

By using triangles of various sizes, a sphere can be symmetrically divided by thirty-one great circles. A great circle is the largest circle that can be drawn around a sphere, like the lines of latitude [Ed. he means longitude] around the earth, or the equator. Each of these lines divide the sphere into two halves, hence the term geodesic, which is from the Latin meaning "earth dividing". The dome is a structure with the highest ratio of enclosed area to external surface area, and in which all structural members are equal contributors to the whole. There are many sizes of triangles in a geodesic, depending on the frequency of subdivision of the underlying spherical polyhedron. The cross section of a geodesic approximates a great-circle line.

Geodesic domes require no load bearing interior walls to support the roof. Interior variations for floor plans within the dome are almost limitless. Interior partitions can be framed directly into the dome shell or may be free standing non-structural space divisions. Sound and visual privacy, floor plan efficiency and human scale can all be maintained and, in most cases, enhanced in a dome home. Unique interior advantages of the dome include: greater freedom of floor plan design; cathedral ceilings without custom design; and unparalleled evenness of light, heat and sound distribution.

In addition to the dome's vast interior variations, the dome shell also offers many exciting exterior possibilities. Because of the unique distribution stresses in the dome shell, up to 50% of the lowest ring of triangles can be removed (most prefabricated dome kits come with 15 of the lower 30 triangles removed.) These non-load bearing openings can then be replaced by walls with conventional doors and windows or by extensions such as greenhouses, garages, carports, sun porches or other conventional structures.Unique exterior advantages of the dome include: greater integration of the dome to many natural environments without custom design, greater structural strength and minimum violation of ground and air space.

Geodesic Living

A dome is more than a collection of triangles. The underlying geometric symmetry, strength and spaciousness of the dome combine to create a feeling of wholeness that is not predicted by simple addition of the individual triangles Although innumerable descriptions of the advantages of "living in the round" have been written by dome home owners, the subjective, intangible advantages have, in most cases, been identified as the most important reasons for living in a dome. The one outstanding feature inherent to all home-sized dome shells is the good feeling you get as you open the door and walk inside.

Dome Energy Savings A sphere represents the least amount of material surface area possible to enclose a given volume of space. When bisected, the half sphere becomes one of the most efficient shapes known to enclose a given floor area. Any "dent" made in the half sphere decreases the area enclosed while the total surface area stays the same.

If the half sphere is dented all the way to a rectangular box like shape, we find that approximately 20% to 30% of the potential interior space is lost. If the box is then dented into a 3-sided pyramid, a tetrahedron, we find a full 66% of the interior space is lost. Most homes, being a combination of rectangular and triangular shapes, fall in the 40% to 60% range. The number one factor affecting the efficient use of materials and energy in any structure is its shape. Many of today's contemporary homes, with vaulted ceilings are the least efficient homes technically possible. By contrast, a typical 1500+ sq. ft. geodesic dome home, with a 23' ceiling height in the living room actually uses almost 20% less material than a typical 1500+ sq. ft. tract home with a 8 ft. ceiling height.

The #1 factor effecting heat loss or gain in any structure is its shape -- Not: -- Thickness of insulation -- Double glazing -- Types of doors -- Type of heat plant . The lower the total outside surface area (ceiling and walls) the greater the heating/cooling savings. Some comparisons would be:

35 ft. diameter dome 23 ft. x 50 ft. box 1161 sq. ft. total (first floor & loft) 1161.5 sq. ft. total 1990 sq. ft. total outside surface area 2337.5 sq. ft. total outside surface area (18% more)

39 ft. diameter dome 22 ft. x 69 ft. box 1518 sq. ft. total (first floor & loft) 1518 sq. ft. total 2480 sq. ft. total outside surface area 2974 sq. ft. total outside surface area (20% more)

45 ft. diameter dome 28 ft. x 79 ft. box 2205 sq. ft. total (first floor & loft) 2212 sq. ft. total 3240 sq. ft. total outside surface area 3924 sq. ft. total outside surface area (21% more)

The percentage in difference, along with the domes perfect heat-flow shape, can add up to a 30% to 50% heating and/or cooling savings. Because domes enclose more space with less material and have high curved ceilings in a substantial area of the floor plan, they display superior light and sound characteristics. Spherical shapes tend to amplify light while rectangular shapes tend to absorb light (Substitute a square lamp shade for a spherical shade and note the intensity difference.) In many cases it is actually brighter inside a dome without any interior lights turned on than it is outside. Acoustical advantages include more even sound distribution, lower volume requirement, and approximately 30% less outside noise infiltration, all due to the dome's lower surface area and unique reflective characteristics.

Special considerations of dome homes

Orientation

Ideally, every home is placed on its property for maximum wind and rain protection, natural drainage, optimum sun exposure, and best use of existing land contours. In most cases, however, the relationship between the shape and size of the lot, dominant views, foundations, driveways, retainer walls, walkways, entries, main access roads and utility access limit the maximum use of the natural environment. In addition, local zoning laws, easements and covenants may further restrict use of the lot. The unique 5-sidedness and omnidirectional character of the dome make it especially versatile for lot placement. Because domes have 5 exterior long walls, the main floor will orient 5, rather than the traditional 4, directions. The upper portion of the dome shell, being near a true round, is equally oriented in all directions. The omnidirectional characteristics of the dome facilitates ideal placements for solar and view advantage. Any of the 60 triangular surfaces (on a 3 frequency, 3/8 sphere) that make up the dome shell can be opened up with skylights for view or solar gain.

With no formal front, back or sides, the dome allows environmental stress such as earth movement (earthquakes) and wind (hurricanes) and snow loading to be evenly distributed throughout the structure. This increases the options for dome placements on rugged, steep terrains and on lots subject to severe weather conditions. Geodesic domes have been used successfully as radar towers in Antarctica under up to 200 mph winds for over 25 years.

Foundations

Vertical concrete or all-weather wood lower floors or basements can be used below the dome shell, to double the first floor area. Also, this vertical orientation of the dome adapts well to narrow or steep sloped lots. Thus, a relatively small, single floor dome can be increased to enclose a large total number of square feet. Other possible type of foundations include perimeter wall, slab, grade beam and half basements.

Riser Walls

Dome riser walls are unique to domes and, when used, are an integral structural unit of the same shell. The use of riser walls is intended to raise the total height of the dome 2 ft. to 7 ft. to achieve more useable area in the dome's loft.

Lofts

The addition of a loft within the dome shell is an attractive and economical way to add more interior space without adding more roof area. Depending on the diameter of the dome and the height of the riser wall, the useable area in the loft will differ. A higher riser wall creates more loft area with 6'-0" head height or more. A good general rule of thumb for rough estimating useable space in the loft is that for every extra foot of riser wall height added, an additional one foot ring of useable area is added to the loft.

Extensions

Additional space can be added to the dome's main floors and/or basements by extending outward from the long wall sections. Solariums, dining coves, rec-rooms, swimming pools, airlock entries and garages and carports have all been successfully extended from dome shells. Existing rooms can also be expanded and eaves added with standard 2'-0" and 4'-0" extensions.

More www.dnaco.net/~michael/domes/domes.html , www3.sympatico.ca/geodome

The Gothic Revival was the architectural style of a newly prosperous Bombay during the years of the cotton boom. Most of the public buildings dating from the 1860's to the closing years of the 19th century were built in this style.

Gothic precinct is the block south of the Flora Fountain. The main attractions here are the high court, the Rajabai tower and the University buildings. The last is the only building in Bombay designed by Sir Gilbert Scott, one of the chief British exponents of this style of architecture.

The Bombay High Court

A splendid Gothic revival building designed by Lt.Col . J . A . Fuller of the Royal engineers , at a cost of Rs. 16,44,558 at against the estimated cost of Rs. 16,47,196 . The work was started in April 1871 and was completed in November 1878 . The length of the building is 562ft, its breath is 187ft and its height is 90ft . While the mid portion of the building rises a further 17ft . On both sides of the building there are separate private staircases used only by the judges. On the groundfloor near the main staircase there are two halls of dimensions 49x22ft . On the west side of the building the two corners have a narrow staircase each .

It consists of ground plus three upper floors. The High Court was built with local black basalt during the late nineteenth century. The chambers are surrounded by Venetian style galleries which are decorated with exuberant carvings of monkeys with scales of justice, foxes wearing barristers' clothes, pigs, tigers and birds cavorting in petrified jungles. The stone masons were unknown local artisans, who were given a free hand .

Initially the Small Causes Court was supposed to be in this building but then a separate small causes court was built . The building comprises of 58 court rooms with attached cabins for the respective judges . On the fourth room there is a records rooms with dimensions 50x60ft . The structure is very imposing and massive but there isnít enough natural light in the court rooms. The court rooms and the galleries have tiled flooring while the other rooms have italian stoned flooring . All the courtrooms are furnished in Burma teak.

The courtroom no: 46 on the second floor is the most impressive courtroom. It is centrally placed below the main roof and it is double storied in height. There is a viewing gallery in this courtroom. It was here that Lokmanya Tilak defended himself by saying, "Swaraj is my birthright and I shall have it". The services of the building havenít been properly laid properly in the intial construction. To cope with the ever increasing number of users later pipelines, electric cables, telephones lines etc. have been incorporated in a hap-hazard manner. This has spoilt the beauty of the structure. This is the only High Court in the world where the main entrance is used exclusively by the judges and rest of the people use the back entrance for transit.

The corridors have Gothic style arches with no Chajja projections as a result all the rain water enters and wets the corridors. In some parts of the building temperarory chajja projections made of coconut leaf mat have been used. The tiled roof has worn out in many places causing leakages in many places. As a whole the entire building needs to be restored and maintained properly.

The University

This is the only building in Bombay designed by Sir Gilbert Scott. Sir George Gilbert Scott was one of the main exponents of the Gothic Revival in Victorian Architecture. He was the architect of the Bombay University building in the Fort area. The library and the 280 feet high Rajabai clock tower, with its marvellous sculpted figures, was funded by the 'Cotton King' and banker, Premchand Roychand.

The convocation hall was funded by the man with the deepest pockets in Bombay-- Sir Cowasji Jehangir Readymoney. This building is inspired by ancient french architecture . Its width is 44ft , its lengh 104ft and height 63ft upto the ceiling . Apart the area of the hall ,the diameter between the last two turrets is 38ft . On the front elevation there is a beautiful gothic style circular design of 7ft . The front terrace is 11ft and the one on the side is 8ft wide. All around the hall there is a 8ft gallery which is provided with a railing of pointed triangular bars .

On entering the building there are two staircases , the railings of these are provided with octangonal small columns with Corinthian order design. This structure is made by making use of porbunder stone . The flooring is of muliticoloured stone while at the main entrance marble flooring has been used . The work commenced on 1st march 1869 and was completed on 31st December 1874 . This is a very small but attractive building with magnificiant gothic windows . The attractive tower is situated in the gardens of the Mumbai University. The 280ft tower gives the fine view of the city.On the first floor there is a hall with a height of 68ft . The design of the hall begins with a square and ends in an octagon . Another hall is at a height of 118ft , and the third hall is at an height of 94ft above the second hall .There is a tower clock which has an inner diameter of 12ft and 6inch and outer diameter of 16ft and 6 inch . The clock is placed above the ceiling of the hall on the third floor . There are in all 282 stairs to the top of the tower and the tower is provided with opening to provide natural light and ventilation . The staircase is very narrow . The ground floor of the library building has two halls . The main staircase is 28 sq.ft behind which there is a narrow octangular part. On the western side there is a tower and the entrance is 28 sq.ft . The wall thickness is 5ft . The height of the building is 152ft . On the two corners of the western side therare spiral staircases . On the first floor there is library and a reading rooms situated in one hall . The typical Gothic styled windows are observed in here

The cost of construction of the clock was 30,000 rupees . The height of the dome is 52ft .The top of the cuppola is ornamented with 16 statues and is about 30ft from the ground.The government santioned Rs 2,80,748 for the library and Rs 2,17,345 for the tower , however the total expenses exceeded these amounts by Rs 5,47,703 . The Rajabai Clock Tower in the University of Bombay, named after mother of Premchand Roychand was built from a donation of rupees 4 lakhs by him, as was the library. The tower was built in 1864-65 . The University of Bombay was build to function as an University . With changing times the number of faculties offered by the university have increased ,as a result 90% of the departments have been shifted to Kalina campus . At present only the Law departments and the post graduation departments are funtional in the campus . The vice-chancellor funtions equally between the fort campus and the kalina campus.The Rajabhai tower contrasts with the Bombay stock exchange building in the background .An observer is distracted by this constrast and is not able to appreciate the style used to build The Rajabhai tower . As soon as we enter the gate of Bombay University ,the huge tower welcomes the visitor . The tower which stands on a huge base with a clock on it always reminds us the importance of time in life . The material used for constructing the tower helps it to stand out . The yellow Porbunder stone is strikingly different from the black basalt stone used in the construction of the adjacent Bombay High Court building . The University campus is laid out such that the library building and Convocation hall face each other . The convocation hall is comparitively a smaller structure while the library building along with the Rajabhai tower is an imposing structure , yet the beauty of both the structures can be equally appreciated .

The stucture which is built in Gothic style puts an impact on the minds of an observer . The prominant arches , columns , windows etc. gives an idea of volume . The spiral staircase gives a feeling of delicacy to the structure .

David Sassoon Library

Looking on to the Kala Ghoda, on Rampart Row, this Romanesque structure, completed in 1870, is built from the same yellow Malad stone as the rest of the buildings in the row-- Elphinstone College, the Army and Navy Building and Watson's Hotel. David Sassoon donated Rs.60,000 out of the total cost of Rs. 125,000 for this building. The rest of the cost was borne by the government. The idea of the library was mooted by twelve mechanics employed in the Bombay Mint. The columns are of black trap and the dressing is in random rubble masonry. The ground floor facade of the three-storied building has pointed arches decorated in white and black stripes protecting the arcade which is characteristic of the area. The foyer with its multicoloured Minton floor tiles, opens, at the back, into a garden. Above the entrance portico is a white stone head of David Sassoon. The first floor is reached by a winding wooden staircase. Turrets at each corner and the central tower give the building a church-like air.

The building was designed by Scott McClelland and Company and built by the architects J. Campbell and D. E. Gosling at the cost of Rs. 125,000. It was presented to the city by Sir Albert Sassoon, the son of David Sassoon.

The ground of the building has been rented to Lund and Blockley Opticians . This building has been recently renovated.The library which is built in Gothic style stands out against the Army-Navy building which is built in a different style.