REINFORCING THE FRAME

![]()

Fr-1

Trim the tab hanging in front of the torsion bar that a portion of the original car pan was welded to. Measure from the top of this tab, to the bottom curve of this tab. Trim it so that it will fit inside of the 1” tube riser we are going to fabricate next. It will help you to get a better Idea by viewing FR-2 and FR-3 before you start trimming.

![]()

Fr-2

Cut out the portion that prevents the bottom of the riser from sliding flush with the trailing edge of your floor pan framework. {SEE FR-3} cut and fit it to the proper length. I prefer to leave it long , so I can clamp it, until I cut the wall out.

![]()

Fr-3

Carefully align it, and tack it in several places. Weld the inside top, sides, and bottom of the riser to the tab and the pan frame. This reinforces the vertical stability, and also links the bottom of the Twin-beam to the torsion bar. It is a structural weld. Now flip the frame over so you can attend to the bottom welds.

![]()

Fr-4

Weld any and all seams on the pan frame that haven’t yet been welded.

![]()

Fr-5

Now weld the riser to the pan framework and to the tab at the rear seam.

![]()

Fr-6

Next cut a piece of 1” angle iron and fit it between the pan framework and the trailing edge of the shock tower. This is a lateral brace for strengthening the beam to the torsion bar. When the pan framework is finished, it will form an assembly that locks the front of the lower beam all the way back to the torsion bar by means of a rigid triangular structure. Weld it all the way around. This is a structural weld.

![]()

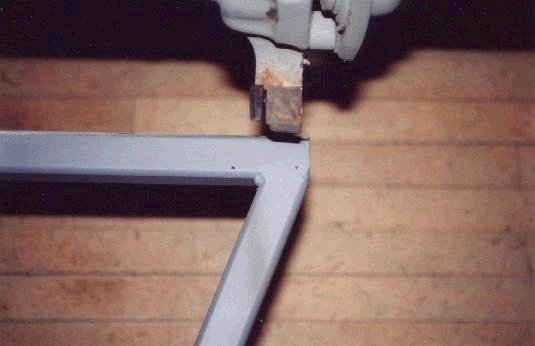

Fr-7

Wire brush and prime the bottom. It should look like this.

![]()

Fr-8

Take a piece of 2” X 2” X 1/4” angle. Make a compound cut, so the front of the angle iron leans foreword paralleling the front beam surface, while the bottom and top of the angle parallel the pan framework and the bottom of the lower Twin-beam. This is a structural weld. It is a lower fairing mount, but it also reinforces the side welds of the lower beam components. Use a flat surface to align these pieces, just as you did for aligning the front bar. { PC-4 } SEE FR-9 for detail. If you weld one crooked, you’ll have a good comprehension of how strong they are...... when you try to knock it off.....like I had the privilege of doing. Just another good reason to double check the angles before you weld it solidly.....like I didn’t.

![]()

Fr-9

Brush and prime the frame.

![]()

Fr-10

Now we are ready to put the front end on the frame. It should look like this.

![]()