Movement Information and Price Lists

Effective 01.01.2011

Kieninger Uhrenfabrik GmbH

Brunnenstraße 37

D-78554 Aldingen

Introduction

Kieninger is the oldest existing manufacturer of mechanical movements for floor, wall and mantel clocks in the world. Kieninger movements

excel with a high level of design and manufacturing quality. Numerous innovations and patents (Kieniramic7 solid anchor, 16-rod chimes;

second indication for pendulum lengths under 116 cm; automatic beat adjustment, nighttime shut-off systems for 1/2-hour and 1/4-hour

movements; automatic chime sequencing; various manufacturing processes and components) are the measure for design quality.

Manufacturing quality shows in every movement: All movement plates are made of a special brass alloy which is hard and has a tensile

strength [Rm] of 520 N/mm2. The holes for the journals are reamed and smoothened after lacquering and then receive an oil sink. Pinions are

made of high-quality steel. Fast turning pinions are hardened. All journals are roller burnished in a special process. Some movements feature

bronze-bushings and/or jewels in critical positions. The gears are made of a very tough and hard brass alloy with a tensile strength of 610

N/mm2. A high level of corrosion protection for all components is assured. Brass components are pickled and receive a coat of clear lacquer.

Steel components are made from stainless steel or receive a galvanic nickel coating. Each movement has a laser engraved serial number.

In the following material you will find an overview of the movement series structure and detailed information for each of the Kieninger movement

groups. In addition, selected pendulums, weights, weight shells, weight fillings and dials as well as mounting and other accessories are listed.

For additional or customer specific movement applications, please contact Kieninger directly or one of our representatives.

Contents

1. Abbreviations

2. Symbols

3. Introduction

4. A small clock glossary

5. Overview movement series structure

6. Prices

7. Volume discount table

8. Movements, mechanical

9. Quartz movements

10. Pendulums

11. Weight shells

12. Weights & Weight fillings

13. Weight requirements

14. Dials

15 .Dimensions

Abbreviations

AM Automatic chime sequence

AZL Winding holes (cable & chain movements) |

COM Comtoise movement

CHR Chrome plated execution

EMS Easy Mount System

GR Maintaining power

HF Flat strike rack assembly (back hammer)

NA Automatic night time shut-off between 10.00 PM and 7.15 AM (1/4-movements) or 7.00 AM (1/2-movements)

PL Nominal pendulum length [cm]

POL Polished execution

PS Pendulum disk [mm]

RA Back winding

S Standard

SEK Off-center true second (PL 116) or correct second indication

TBS Dancer module

USS Chime selector slots

ZW Hand shaft length (see table on page 35)

X Option available

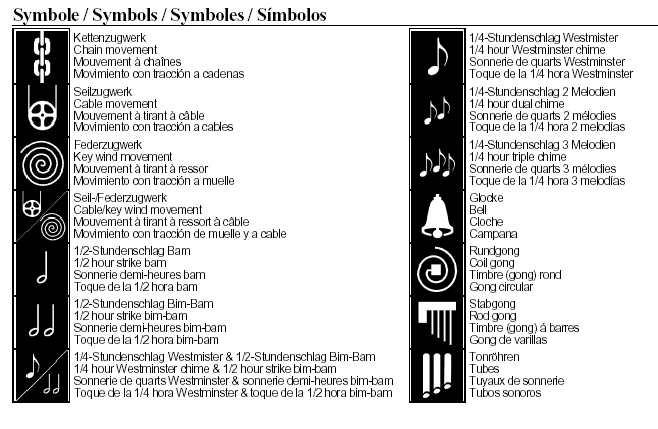

Symbols

Tubes

1/4 hour Westminster chime & 1/2 hour strike bim-bam

Rod gong

1/2 hour strike bim-bam

Coil gong

Gong circular

1/2 hour strike bam

Bell

Cable/key wind movement

1/4 hour triple chime

Key wind movement

1/4 hour dual chime

Cable movement

1/4 hour Westminster chime

Chain movement

Kieninger Clock Movements