ABSTRACT

Hazardous or

uncomfortable working conditions, repetitive tasks, difficult

handing, and multi-shift operations demands use of robots in

industrial situations. They are greatly applied in production

situations. Such as materials transfer, machine loading, welding,

sprays coating, process operations, assembly, and inspection.

Material transfer robot includes pick and place operations.

Computer Aided Manufacturing (CAM) systems involves the use of

industrial robots to perform a portion of the parts handing chore.

Pick and place robots are used to move work parts between the

machine and to orient and locate the work parts for processing at

the machines. This paper describes a simple low-cost pick and

place type robotic system is designed to transfer the work parts

from one place to another. Pick and place operations are

controlled through PC by using add-on card. One can pick the

object and place at a position decided by user using PC. Software

is developed for deciding angle through which the robot arm moves

pick and place positions and activation of sensor.

Introduction

- The completely automated and integrated

environment consists of computers, PLCs, NCs, CNCs or DNC

machine robots, database management system (DBMS), LAN

based instrumentation and graphical user interface (GUI)

based software.

- Robot is an integral part of the computer

aided manufacturing (CAM) systems for providing

flexibility, high productivity and improving the quality

product consisting of faster operations and hazards

situations.

Motivation

- Robots are ideally suited for any

repetitive job, which is regarded as too boaring or too

tedious for human operators.

- For such situations pick and place robot

is an ideal solution where more flexibility is not

desired. This paper describes fabrication of a simple

robot for a small production line or work-cell2.

Designing of pick and place

robot

- A robot is a re-programmable,

multifunction manipulator designed to move material, and

parts, tools or specialised devices through variable

programmed motions for the performance of a variety of

tasks2.

- Another generalised definition of robot is

that an industrial robot is a general purpose,

programmable machine possessing certain anthropomorphic

characteristics.

- Design and fabrication of a robot is

mainly divided into three major aspects namely:

Mechanical, Electronics, and Interfacing to PC

Mechanical aspects:

- The main mechanical part in pick and place

robotic system is to fabricate a robotic arm.

- Basically the robotic arm is designed for

the application such that it can hold both the solenoid

actuator and the object.

- One end of the arm is fixed which is

mechanically coupled to the shaft of the stepper motor so

that it can be moved in angular direction.

- The second end of the arm consists of

solenoid actuator mechanically coupled to the arm, which

is used to pick and place the object from one position to

the other at desired angle.

- The stepper motor with robotic arm is

mounted on a metallic base-table. The torque of the motor

is 1/2 kg. The counterweight is added to balance the

mechanical system.

Electronics aspect:

- For the controlled movement of robotic arm

at a desired position, electronic control circuit is

designed.

- It consists of stepper motor controller IC297

and dual full bridge driver IC2983.

- Stepper controller generates four phase

drive signals for stepper motor in PC controlled

application.

- The motor can be driven in half step and

full step mode. On chip PWM chopper circuit permits

switch mode control of the current in the winding. A

feature of this device is that it requires external clock,

mode input, and direction signals.

- The phase sequence is generated internally.

Hence programming burden is highly reduced for

interfacing purpose.

- IC L298 is high voltage and high current,

dual bridge driver.

- It accepts TTL logic levels at the input

and it can drive inductive load.

- The bridge is grounded through current

sense resistors.

- Current mode PWM maintains the torque at

high speed.

- Stepper motor of rating 12V/500mA is

selected for the present application.

- The controller supply is +5 V and driver

supply is +12 V. The diodes are used as a feedback diode

to return the energy to the supply in the off time of PWM.

- These fast switching diodes also protect

the driver transistors during off time.

Interfacing to PC:

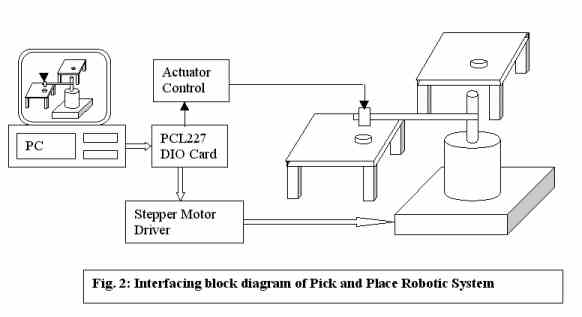

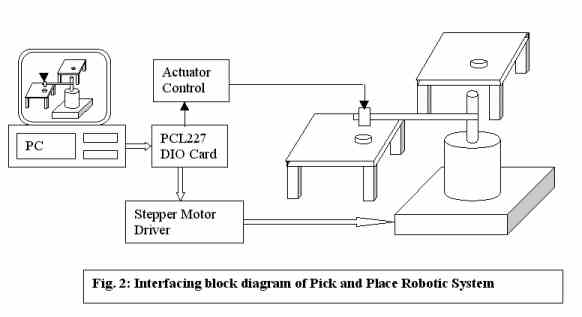

- Figure-2 shows the interfacing block

diagram of the pick and place robotic system.

- System consists of digital input output (DIO)

PC add-on card, stepper motor controller circuit and

robotic arm. DIO card, PCL227 supplied by Dynalog Systems4

is used in the present system.

- The control software ROBO is

designed developed and implemented so as to integrate,

mechanical, electronics and computer interface cards for

a simple assembly line.

- Figure-3 indicates flowchart of the

control software ROBO. The flowchart itself is

self-explanatory. After initializing the hardware, the

pick and place positions, and the actuation current of

the electromagnetic actuator are decided.

Results and Discussion

- Pick and place robot has been designed to

move the work parts from one position to another.

- The system is implemented with a proper

integration of the respective mechanical, electronics and

computer hardware and software.

- This software has been developed under

Turbo C/C++ environment.

- It is completely tested for consistency

and reliability for the precise movement of the arm.

- The pick and place positions can be

precisely selected with minimum angle of rotation of ± 0.90.

- It has been observed that by changing the

activation current of the electromagnetic actuator, the

amount of weight that could be picked up also varies

linearly.

- By setting the actuation current,

different objects having different weights could be

sorted out.

- Selection of specific object from a lot of

objects can also be implemented. This work in this

direction is in progress.

References:

- B. Hodges, "Industrial Robots",

Jaico publishing house (1993).

- Groover, Mikell P.Groover, Zimmers, JR.

"CAD/CAM : Computer-Aided Design and Manufacturing

",Printice Hall of India Private Ltd.( 1992).

- SGS-THOMSON MICROELECTRONICS "Industrial

and Computer Pheripheral Ics " DATA BOOK, (Oct. 1988).

- Installation and Operating Manual of PCL-227

DYNALOG MICRO SYSTEMS PVT.LTD. (1996).