|

|

OK. YOUíVE GOT A SECTION COMPLETED..SMALL PROBLEM HERE..THE SECTION IS CURVED, BUT THE 1/2" PLYWOOD RIDING SURFACE IS NOT..MAYBE YOUíVE TRIED BENDING IT TO MATCH THE CURVE..NOT EASY IS IT? ITíS TOUGHER BECAUSE YOU HAVE TO PLACE THE PLYWOOD ON THE COMPLETED FRAME LENGTHWISE, WITH THE GRAIN GOING UP THE RAMP.

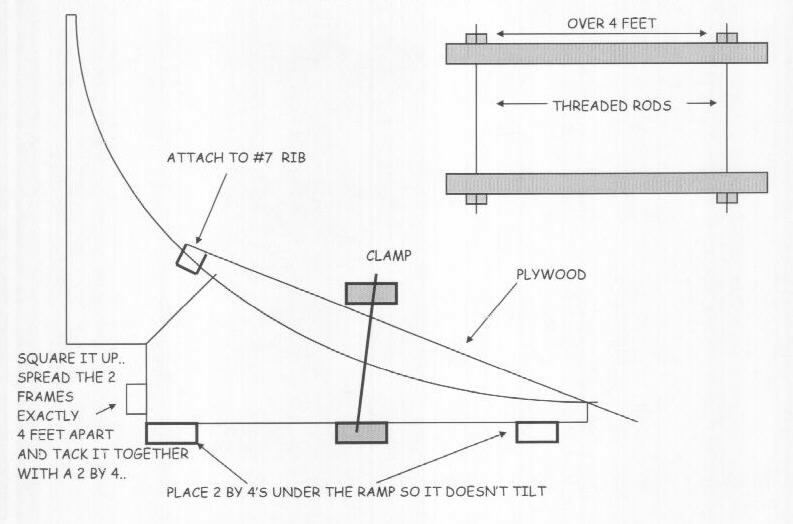

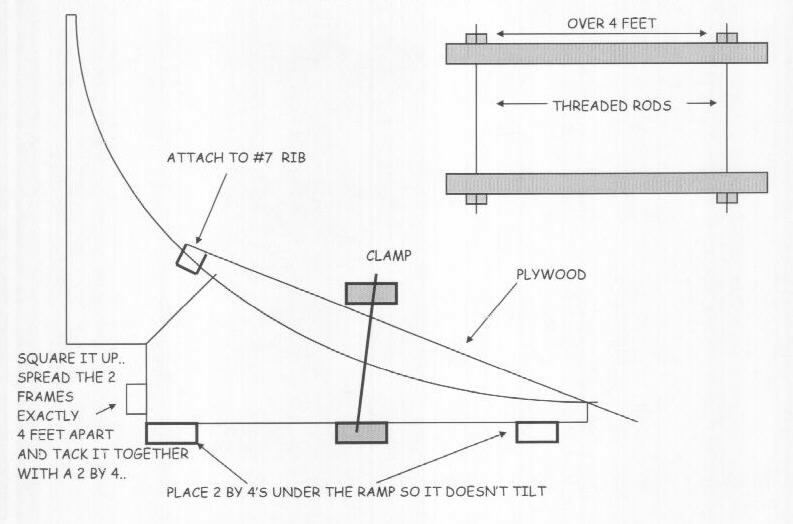

THIS IS SO BECAUSE YOU WANT TO RIDE WITH THE GRAIN, RIDING AGAINST IT WILL RIP UP THE PLYWOOD FASTER, UNLESS OF COURSE,YOU CHOOSE TO COVER IT WITH MASONITE (VERY DRY AREAS ONLY!!) OR SKATELITEÔ , THEN IT DOESNíT MATTER, BUT ASSUMING YOU DONíT... TRY THIS: FIRST..SECURE ALL THE RIBS TO THE RIB SUPPORTS WITH THE NUTS,,CRANK ĎEM DOWN GOOD..GET A COUPLE 1/4" THREADED RODS, ABOUT 3 FEET LONG..GET LARGE WASHERS AND NUTS TO MATCH. CUT 2 PIECES OF 2 BY 4, AT LEAST 4 1/2 FEET LONG, AND DRILL HOLES AT THE ENDS FOR THE RODS TO GO THROUGH..MAKE SURE YOU HAVE AT LEAST 4 FEET BETWEEN THE HOLES....

***DISREGARD THE NOTE ON THE ABOVE DRAWING "ATTACH TO #7 RIB"*** LET SOME PLYWOOD OVERHANG OFF THE FRONT OF THE RAMP TO ALLOW FOR THE AMOUNT OF WOOD THE CURVE WILL SUCK IN.

PUT THE CONTRAPTION TOGETHER

ON THE RAMP AS SHOWN..WHAT YOUíVE CREATED IS A GIANT CLAMP..YOU TURN THE

NUTS WITH A WRENCH, AND IT PULLS THE PLYWOOD DOWN TOWARD THE FRAME..ITíS

ACTUALLY EASIER TO DO IT WITH THE RAMP ON ITíS BACK, BUT ANYHOW, MAKE SURE

THE RAMP DOESNíT TWIST AS YOUR DOING THIS..THEREíS A LOT OF FORCE BEING

EXERTED ON THE FRAME, AND IT NEEDS TO BE ON A HARD, LEVEL SURFACE YOU MAY

NEED 2 OF THESE TO GET THE WHOLE PIECE OF PLYWOOD THE MATCH THE CURVE..YOU

GET THE 1/4" THREADED RODS AS APPOSED TO 1/2" BECAUSE THE 1/4" WILL BEND

WITH THE FORCE, INSTEAD OF THE CLAMP CREEPING DOWN THE CURVE..IT STILL

HAPPENS, BUT NOT AS MUCH. WHEN YOU GET THE PLYWOOD TO MATCH THE CURVE TIGHT,

SCREW IT INTO THE 2 BY 4 RIBS WITH THE # 10 2 INCH SCREWS .. ADJUST THE

BLADE ON YOUR SKILL SAW SO IT DOESNíT CUT INTO THE FRAME AND CUT THE PLYWOOD

AT THE BOTTOM OF THE RAMP AS STRAIGHT AS POSSIBLE, IT HAS TO MATCH THE

PLYWOOD OF THE FLAT PLATFORM , WHICH IS THE 8 FOOT

CONNECTOR TO EACH QUARTER

PIPE. THE SECOND PIECE UP THE RAMP HAS TO BE CUT TOO..IT WILL BE TOO LONG..

SO...BEND THE PLYWOOD, SQUARE IT,SCREW IT IN, AND CUT

IT, AND YOUíVE GOT YOUR FIRST 1/4 PIPE.

**IVíE

HEARD A WAY TO BEND THE PLYWOOD IS TO WET IT DOWN FOR ABOUT AN HOUR AND

IT FLEXES EASIER.. NEVER TRIED IT MYSELF..BUT I KNOW PLYWOOD LIKES TO DELAMINATE,

AND ALTHOUGH WETTING IT FOR A HOUR WONíT DO IT, IT MAY SHORTEN ITíS LIFE.......