A through inspection is the most cost effective way to catch a small defect that might otherwise cause the pre-mature failure of your string and loss of your well.

After a complete inspection

the following specialized services are

offered to inject new life into your

drill string.

Special tools developed

by Tuboscope enable us to reface and

damaged seal area on-field saving costly

down-time and enabling the drill string

to be used again immediately.

![]()

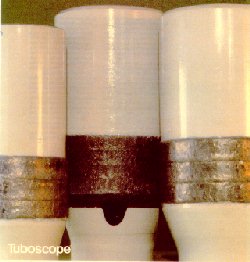

The

careful bonding of hard metal like

tungsten carbide to tool joint steel

will protect the OD from down hole

abrasion. Without such protection, the tool joint

can wear until it becomes too thin

to be safely run. Such wear also reduces

the torsional capacity of the connection

leading to significant expenses , especially if

the drill string parts down-hole.

The

careful bonding of hard metal like

tungsten carbide to tool joint steel

will protect the OD from down hole

abrasion. Without such protection, the tool joint

can wear until it becomes too thin

to be safely run. Such wear also reduces

the torsional capacity of the connection

leading to significant expenses , especially if

the drill string parts down-hole.

Drill collars, heavy weight drill pipe and other bottom hole assembly components are often protected with hard-facing as well.

The theory is to protect all the drill string components that make intermittent contact with the inner surface of the hole, especially in abrasive formations. The wear is more significant in open hole drilling than in cased wells.

When drilling through

casing it is important to minimize

wear to the ID of the casing. Properly

hard-faced tool joints when run with

proper drilling practices have proven to

cause less wear to casing than tong-cut

tool joints or even rubber drill pipe

and casing protectors run in the presence

of sand.

Metallurgical know-how every step of the way

The hard facing procedures and materials adopted by Tuboscope Inc., reflects the latest technologies in bonding one metal to another. The Selection of raw hard metals and sizing of hard facing particles is extremely critical. The temperature during pre-heat and welding is precisely regulated. The cooling procedure is as important to the success of the job as the welding itself. Collectively , no company can offer more background and experience in drill string hard facing than Tuboscope Inc.

Complete selection of Surface Materials

To meet customer requirements

, Tuboscope Inc., offers the most complete

range of materials and welding procedures

in the industry. From the very hard

surfaces required for certain open-hole operations

to several types of extremely smooth

surfaces applicable to cased hole drilling.

In other words , it is safe to say that you can trust your drill string hard facing needs to Tuboscope, Inc., the people who know pipe inside and out.

Web

Site created and maintained by

Jayesh Bhatt at Tuboscope , Indonesia.

Copyright

© 1998 [Tuboscope]. All rights reserved.

Revised:

January 01,1998