The Space Shuttle has three major components: the orbiter, the solid

rocket boosters, and the external fuel tank. The external fuel tank is

the only piece of hardware that is not reused and burns up in the atmosphere

and falls into the ocean after it is jettisoned from the orbiter. The external

tank is made up of a liquid oxygen tank, a liquid hydrogen tank, and an

intertank. These components have been improved since the inception of the

Space Shuttle and now the materials are lighter weight and stronger. There

have also been ideas of placing the external tank into orbit and using

them as a space station for research, living quarters, and even entertainment.

The challenge of converting these external tanks has caused some problems

and this idea is still only perceived in theory.

The external fuel tank on the Space Shuttle is the

largest single integral part of the Shuttle system. According to Damon

(1995), “The external tank (ET) serves two purposes: it carries the propellants

for the orbiter’s three main rocket engines and it is the support structure

that connects the orbiter and solid rocket boosters (SRBs) together during

ascent to orbit” (p. 133). This paper will be an in-depth analysis of the

history and development of the components that make up the ET and also

the new structure that is being designed to decrease its weight. There

have also been ideas of placing the ET into an orbit and using them for

space or refueling stations. These issues and more will be discussed in

detail in the following report.

The concept of a reusable spacecraft is nearly

as old as that of flying machines itself. As the development of rocket

propulsion systems increased, the idea of entering space became a reality.

With this technology, the United States begun its research to construct

a vehicle that could be reused over and over again. On January 5, 1972,

President Nixon approved the three-element Space Shuttle consisting of

an Orbiter, rocket boosters, and a disposable propellant-tank (Gatland,

1981). This was the answer that has worked since the first test flight

on April 12, 1981 (Damon, 1995).

In 1975, the prime contractor for the ET was Martin Marietta

Aerospace. The first ET was assembled at the Michoud Assembly Facility

(MAF) in New Orleans, Louisiana in 1976. In July 1977, the fabrications

for the first flight ET began. The intertank structural test program was

completed in November 1977, and the first ET tanking test was conducted

in December 1977. After all the testing was completed, the first flight

ET (External Tank-1) was delivered to Kennedy Space Center in July 1979

(The External Tank, 1997).

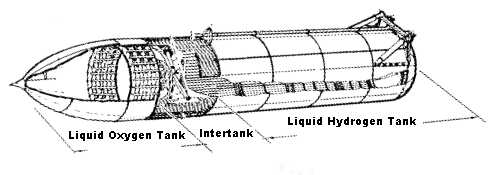

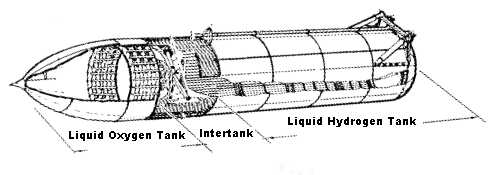

“The ET has three major components: the forward liquid oxygen tank, an unpressurized intertank that contains most of the electrical components, and the aft liquid hydrogen tank” (Dumoulin, 1988, p. 1). See Appendix A for picture of all the components. It is 154 feet long and 27.6 feet in diameter and carries more than 535,000 gallons of cryogenic propellants that are fed to the orbiter’s three main engines (LaNasa, 1997). “Prior to propellant loading, the ET weighs approximately 66,0000 pounds. But once liquid oxygen and liquid hydrogen are loaded into the vehicle beginning eight hours prior to Shuttle launch, the ET weighs 1.65 million pounds” (LaNasa, 1997, p. 1). The first five ET’s weighed approximately 77,000 pounds inert, which made it a heavyweight tank compared to the 66,000-pound lightweight tank.

The upper tank carries 1.36 million pounds of liquid oxygen at minus 297 degrees Fahrenheit (F) at liftoff (Damon, 1995). It is 331 inches in diameter, 592 inches long, and weighs 12,000 pounds empty with a volume of 19,563 cubic feet (143,000 gallons). See Appendix B for a picture of the liquid oxygen tank. Dumoulin (1988) describes its construction as follows:

“An intertank collar connects the two propellant tanks together and provides space for most of the electrical components” (Damon, 1995, p. 134). The intertank is 270 inches long, 331 inches in diameter, and weighs 12,100 pounds. See Appendix C for a picture of the intertank. Dumoulin (1988) better describes the configuration of the intertank as follows:

“The lower tank is about 2.5 times larger (383,000 gallons) and carries about a quarter of a million pounds of liquid hydrogen at minus 423 degrees F” (Damon, 1995, p. 133). It is 331 inches in diameter, 1,160 inches long, and 53,518 cubic feet of volume and weighs 29,000 pounds empty. The liquid hydrogen tank’s composition is specified below:

“The entire outer surface of the external tank is insulated with a half inch thick cork/epoxy layer covered with 1 to 2 inches of spray-on foam” (Damon, 1995, p. 134). “The system also includes the use of phenolic thermal insulators to preclude air liquefaction. Thermal isolators are required for liquid hydrogen tank attachments to preclude the liquefaction of air-exposed metallic attachments and to reduce heat flow into the liquid hydrogen. The thermal protection system weighs 4,823 pounds” (Dumoulin, 1988, p. 4) The two reasons protection is essential are because both propellants are very cold and they boil at very low temperatures. The following are problems that could happen if there was no insulation (Damon, 1995):

The external hardware, ET / orbiter attachment fittings,

umbilical fittings, electrical, and range

safety system weigh 9,100 pounds. Each propellant tank has a vent and

relief valve at its forward end. This dual-function valve can be opened

by ground support equipment for the vent function during prelaunch and

can open during flight when the ullage (empty space) pressure of the liquid

hydrogen tank reaches 38 psig or the ullage pressure of the liquid oxygen

tank reaches 25 psig. The liquid oxygen tank contains a separate, pyrotechnically

operated, propulsive tumble vent valve at its forward end. At separation,

the liquid oxygen tumble vent valve is opened, providing impulse to assist

in the separation maneuver and more positive control of the entry aerodynamics

of the ET. There are eight propellant-depletion sensors, four each for

fuel and oxidizer. The fuel-depletion sensors are located in the bottom

of the fuel tank. The oxidizer sensors are mounted in the orbiter liquid

oxygen feed line manifold downstream of the feed line disconnect. During

SSME thrusting, the orbiter general-purpose computers constantly compute

the instantaneous mass of the vehicle due to the usage of the propellants.

Normally, main engine cutoff is based on a predetermined velocity; however,

if any two of the fuel or oxidizer sensors sense a dry condition, the engines

will be shut down. The locations of the liquid oxygen sensors allow the

maximum amount of oxidizer to be consumed in the engines, while allowing

sufficient time to shut down the engines before the oxidizer pumps cavitate

(run dry). In addition, 1,100 pounds of liquid hydrogen are loaded over

and above that required by the 6-1 oxidizer / fuel engine mixture ratio.

This assures that MECO from the depletion sensors is fuel-rich; oxidizer-rich

engine shutdowns can cause burning and severe erosion of engine components.

Four pressure transducers located at the top of the liquid oxygen and liquid

hydrogen tanks monitor the ullage pressures. Each of the two aft external

tank umbilical plates mate with a corresponding plate on the orbiter. The

plates help maintain alignment among the umbilicals. Physical strength

at the umbilical plates is provided by bolting corresponding umbilical

plates together. When the orbiter GPCs command external tank separation,

the bolts are severed by pyrotechnic devices. The ET has five propellant

umbilical valves that interface with orbiter umbilicals: two for the liquid

oxygen tank and three for the liquid hydrogen tank. One of the liquid oxygen

tank umbilical valves is for liquid oxygen, the other for gaseous oxygen.

The liquid hydrogen tank umbilical has two valves for liquid and one for

gas. The intermediate-diameter liquid hydrogen umbilical is a recirculation

umbilical used only during the liquid hydrogen chill-down sequence during

prelaunch. The ET also has two electrical umbilicals that carry electrical

power from the orbiter to the tank and the two SRBs and provide information

from the SRBs and ET to the orbiter. A swing-arm-mounted cap to the fixed

service structure covers the oxygen tank vent on top of the ET during the

countdown and is retracted about two minutes before lift- off. The cap

siphons off oxygen vapor that threatens to form large ice on the ET, thus

protecting the orbiter's thermal protection system during launch (Dumoulin,

1988).

The range safety system provides for dispersing

tank propellants if necessary. It includes a battery power source, a receiver/decoder,

antennas, and ordnance. Various parameters are monitored and displayed

on the flight deck and control panel. These parameters are then transmitted

to the ground (Dumoulin, 1988).

The first weight reduction of 10,000 pounds in April 1983 resulted in increased payload. Now a new design will weigh another 7,500 pounds less. This lighter weight will allow the Space Shuttle to carry heavier cargo into orbit, which is a key element in building the international space station (Cabbage, 1995).

Parker Counts, manager of the External Tank Project at the Marshall Space Flight Center said, “The new external tank has passed one of the most innovative structural verification test programs ever designed, culminating with these proof tests” (Rahn & Malone, 1997, p. 1). The following is a description of the sate of the art test technology:

The following is a schedule of events that happen to the ET during a Space Shuttle launch. The time is displayed first, followed by the event (Damon, 1995):

There has been many ideas brought forward to use the ET as a space station or even a refueling station. “Martin Marietta has proposed modifying one tank to serve as a pressure vessel to house a gamma ray imaging telescope. Another possible use which has been proposed is as an orbital fuel storage facility to support on-orbit operations” (Bridwell, 1997, p. 2). “Some planners envision them clustered together as a space station, fitted with rockets and launched to the Moon for a lunar colony, or refitted a little at a time and used as orbiting gas stations for vehicles heading to the outer reaches of the Solar System” (Damon, 1995, p. 146). See Appendix D for a picture of the Space Station concept. The following is a simple idea for a space station:

The following is a portrayal from Tom Abbott, an ET enthusiast, of how an ET would be outfitted in orbit:

The technical challenges of placing an ET into orbit

include the circularization and maintenance of orbit, the cleanup and evacuation

of residual liquid oxygen and liquid hydrogen, and dealing with the foam

insulation (Fitch, 1997). There have been many different ideas of how to

solve these problems and they will be discussed further in the following

paragraphs.

The first problem is to get the ET in a circular

orbit and keep it there. “If left in a very low Earth orbit, the tanks

would have to be periodically boosted to higher altitude to keep them from

becoming a hazard to traffic and from eventually burning in. A costly alternative

is to strap on rockets and boot them to a higher stable parking orbit”

(Damon, 1995, p. 146). With that, some form of attitude jets would need

to be attached, plus a way to remotely control them. Tom Abbott said, “In

all on-orbit ET space station conversion proposals, a propulsion system

is installed just as soon as is practical and the ET remains attached to

the Space Shuttle until the is accomplished. Positive control of the ET

at all times is the only acceptable way to operate” (Fitch, 1997, p. 1).

When the Space Shuttle jettisons the ET, there are

from 5 to 20 tons of residual fuels remaining in the tank, and something

has to be done with them (Fitch, 1997). Tom Abbott said, “According to

a study undertaken at the direction of the ET Project Office, there are

three ways to accomplish this: (a) through the Orbiter’s fill and drain

valves, (b) through the Orbiter’s engines, and (c) through the ET vent

and relief valves. The first method is recommended. The second method has

the disadvantage that the vented hydrogen could affect the engine unfavorably,

and the third method requires modifications to the ET” (Fitch, 1997, p.

3).

There is concern that the Spray-On-Foam Insulation

(SOFI) could erode in orbit and cause annoying and potentially dangerous

debris (Fitch, 1997). Tom Abbott suggests his solution. “After the

ET reaches orbit, it can be held in a 170 mile high orbit while the SOFI

is scrapped off. One study predicts it would take less than a week to strip

the SOFI, and debris would deorbit in from hours to a couple of days, depending

on the size of the piece. Another is to leave the ET in a 160 mile orbit

for about a month and all the SOFI would oxidize off of it” (Fitch, 1997,

p. 4).

The ET is an important piece of equipment and without

it, the Space Shuttle would never make it into space. There have been many

improvements since the first ET was constructed, resulting in more payload

for the Shuttle to carry into space. These lighter weight designs have

even proved to be stronger and they provide more stability. As technology

expands, the reality of placing an ET into orbit and using them as a space

station could possibly happen. I feel this will happen in the near future,

basically because of the efforts by Gene Meyers and his Space Island Project.

It is best said by Bridwell (1997), “The ET is a proven, reliable piece

of hardware. The recently completed reassessment has only reinforced my

conviction that the tank will provide reliable service for many years to

come and will be the basis for many innovative adaptations” (p. 2).

Abbott, T. (1997). Outfitting an external tank in

orbit. [On-line]. Available: http://www.vswap.com/fitch/text/et_tom.htm

Ball, N., DeFilippo, R., Ritter, M., Skryd, K.,

and Ball, J. (1997). Space manufacturing and processing. [On-line]. Available:

http://cher.eda.doc.gov/oasc/spcmfg.html

Bridwell, P. (1997). External tank. [On-line]. Available:

http://spacelink.nasa.gov/NASA.Projects/….to.Flight/External.Tank-Porter.Bridwell

Cabbage, M. (1995, December 24). NASA working to

decrease weight of shuttle fuel tanks. Gannett news service, p. 1

Damon, T.D. (1995). Introduction to space. Malabar,

FL: Krieger Publishing Company

Dumoulin, J. (1988). External tank. [On-line]. Available:

http://www.ksc.nasa.gov/shuttle/technology/sts-newsref/et.html

Fitch, C.A. (1997). External tanks in orbit. [On-line].

Available: http://www.vswap.com/fitch/text/et_orb3.htm

Gatland, K. (1981). The illustrated encyclopedia

of space technology. New York, NY: Harmony Books

LaNasa, M. (1997). Space shuttle external tank.

[On-line]. Available: http://www.lmco.com/michoud/etfact1.html

NASA: Shuttle’s new lighter, stronger external tank

completes major pressure tests. [On-line]. Available: http://www.elibrary.com/getdoc.cgi?id=87…ydocid=522000@library_e&dtype=0~0&dinst=

Nead, A. (1997, November 12). First super lightweight

tank achieves major production milestone. [On-line]. Available: http://www.lmco.com/michoud/Slight.htm

Prado, M. (1997). Shuttles throwaway external tank.

[On-line]. Available: http://www.permanent.com/ext-tank.htm

Rahn, D. & Malone, J. (1997). Shuttle’s new

lighter, stronger external tank completes major pressure tests. [On-line].

Available: http://nexus.nasa.gov/Now/News/PAOArchive\97-058.html

The external tank. (1997). [On-line]. Available:

http://www.primenet.com/multimedia/space/rings.htm

Williams, N.P. (1997). Space shuttle super lightweight

tank. [On-line]. Available: http://www.lmco.com/michoud/slwtank.html

Source: (Damon, 1995)

Source: (Dumoulin, 1988)