History of Cars ~ Part 2

![]()

In the traditional steam engine, and even in a modern steam turbine, fuel is burned outside the engine. But it is more efficient to burn fuel inside the engine and let the expanding gases produced drive a piston or turbine.

The first such internal combustion engine, running on gas, was build by the German engineer Nikolas August Otto (1832-91). His engine, demonstrated in Paris 1867, was large, noisy and not very efficient. But it became the forerunner of 99% of all today's engines.

The

four stroke cycle

The

four stroke cycleNine years after the first gas engine Otto devised another, based on the four-stroke cycle. The crucial advance in this engine was ignited, giving not only a considerable improvement in efficiency but also a marked reduction in fuel consumption.

It takes four strokes of the engine to include one of power, so this system is known as the four-stroke cycle. It is by far the most common type of engine in use today. The four main stages are an induction stroke in which a downward movement of the piston sucks in the fuel-air mixture; a compression stroke in which upward movement caused by the explosion of the fuel; and an exhaust stroke in which the upward-moving piston forces exhaust gases out of the cylinder.

Many motor cycles and few small cars use the two-stroke cycle first devised by Dugald Clerk in 1880. In this type of engine the movement of the piston admits the fuel and exhausts the burned gases by uncovering "ports" or holes in the side of the cylinder.

Fuel and exhaust pass in and out of a four-stroke engine using a more sophisticated system of valves, controlled automatically by a camshaft driven direct from the engine's crankshaft. As the engine operates, the valves are successively opened and closed.

The moment of ignition of the fuel must also be accurately controlled. This is done by a distributor, again mechanically connected to the crankshaft, which directs a current of electricity successively to each of the cylinders. This current "fires" a spark in the sparking plugs and the fuel is ignited.

Otto's engines ran on coal gas, a perfectly satisfactory fuel but one that is difficult to store. The gas engine was greatly improved by the use of liquid fuels such as petrol (gasoline) made by refining crude oil. To turn petrol into a combustible vapor it is mixed with air to form a fine mist of droplets that can be drawn into the cylinders. The mixing is carried out in a carburetor.

Unlike steam engines most internal combustion engines do not produce great power at slow speeds. The cylinders are small and each individual ignition stroke produces comparatively little power. To obtain a useful amount of work from such engine it must be run fast, to put the maximum number of ignition strokes into each second. Motor car engines commonly produce their maximum power at speeds of 5,000 revolutions per minute or more. The oscillating pistons and valve gear sets the upper limit on speed. Specially prepared engines, in which great attention has been paid to balance and smoothness, can be obtained more power by running into speeds of 12,000 rpm or more.

The compression-ignition engine, designed by the German Rudolf Diesel (1858-1913) in 1896, dispenses with the carburetor and sparking plugs of the petrol engine. The gas inside the cylinder on the compression stroke is pure air, which is compressed to 1 : 14 to 1 : 20 of its initial volume - a much higher compression ratio than is used in petrol engines. At the top of the compression stroke a fine spray of oil fuel is injected into the cylinder. As gas is compressed its temperature increases, so that the oil spray meets the air charge at a temperature sufficiently high to ignite it spontaneously.

Because of its high compression ratio the compression-ignition or diesel engine is more efficient than a petrol engine. But for the same reason it must be more heavily built, thus offsetting the advantage somewhat. Diesel engines offer economies in fuel consumption at the expense of a loss in performance; they are particularly suited to frequent stop and start duties, and as a result are widely used in taxis, buses and lorries.

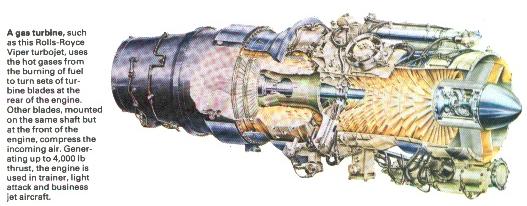

The  gas

turbine, a completely different kind of engine, was first devised at the

beginning of the twentieth century (1900s) and perfected in the 1930s. It

usually has a single shaft carrying a series of propeller-like fans divided into

two groups, the compressor and the turbine.

gas

turbine, a completely different kind of engine, was first devised at the

beginning of the twentieth century (1900s) and perfected in the 1930s. It

usually has a single shaft carrying a series of propeller-like fans divided into

two groups, the compressor and the turbine.

In an operating gas turbine air is drawn in the compressor fans and its pressure increased. The compressed air is mixed with fuel and ignition takes place, further increasing temperatures and pressures. The burned mixture leaves the engine through the turbine, driving the blades round. The compressor, which is often driven directly by the turbine, takes up much of the power produced, but enough is left to make the gas turbine exceedingly powerful form of engine. Efficiencies are not high, but the good power-to-weight ratio of a gas turbine makes it suitable for aircraft propulsion. A gas turbine is about three times as powerful as a piston engine of the same weight.

![]()