Hardness

Testing

During

the manufacturing process of any metal

products , there is the process of heat

treatment and then of quenching. This is

the uniform cooling of the heated product

to obtain the desired strength. This process

is dependent on numerous variables and

has to be verified that it is

carried out properly. If this is done

in-correctly , there may be hard / soft spots

which would during usage deteriorate rapidly.

During

the manufacturing process of any metal

products , there is the process of heat

treatment and then of quenching. This is

the uniform cooling of the heated product

to obtain the desired strength. This process

is dependent on numerous variables and

has to be verified that it is

carried out properly. If this is done

in-correctly , there may be hard / soft spots

which would during usage deteriorate rapidly.

To avoid catastrophic

failures due to weak spots , Hardness values

of critical components are often ascertained.

Tuboscope Indonesia carries out Brinell Hardness

Testing at numerous locations over Indonesia

and this is done with sophisticated

electronic equipment giving immediate reliable

readings.

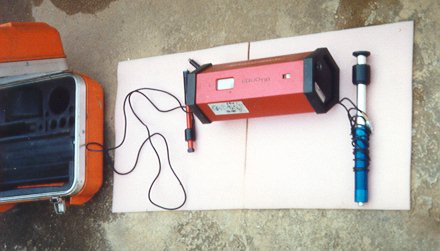

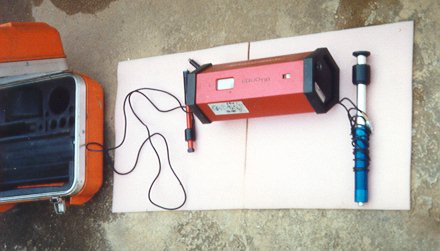

The portable equipment

consists of a plunger with a calibrated

spring mechanism. In this plunger a metal

pellet is injected with precise force

and this is reflected by the material

under test.

The return velocity of

the pellet is measured with the calibrated

spring mechanism. This is then translated

by a portable computer into a value

called the Brinell Hardness Number or

BHn.

Please contact Tuboscope

, Indonesia for further information.

Web

Site created and maintained by

Jayesh Bhatt at Tuboscope , Indonesia.

Copyright

© 1998 [Tuboscope]. All rights reserved.

Revised:

January 01,1998

During

the manufacturing process of any metal

products , there is the process of heat

treatment and then of quenching. This is

the uniform cooling of the heated product

to obtain the desired strength. This process

is dependent on numerous variables and

has to be verified that it is

carried out properly. If this is done

in-correctly , there may be hard / soft spots

which would during usage deteriorate rapidly.

During

the manufacturing process of any metal

products , there is the process of heat

treatment and then of quenching. This is

the uniform cooling of the heated product

to obtain the desired strength. This process

is dependent on numerous variables and

has to be verified that it is

carried out properly. If this is done

in-correctly , there may be hard / soft spots

which would during usage deteriorate rapidly.