Redesign of

Furniture & Fixtures for Bombay Suburban Trains

Anshuman

Singh, Guide: Prof.

U.A. Athvankar IDC,IIT

Bombay, Powai,Bombay 400 076

General Description

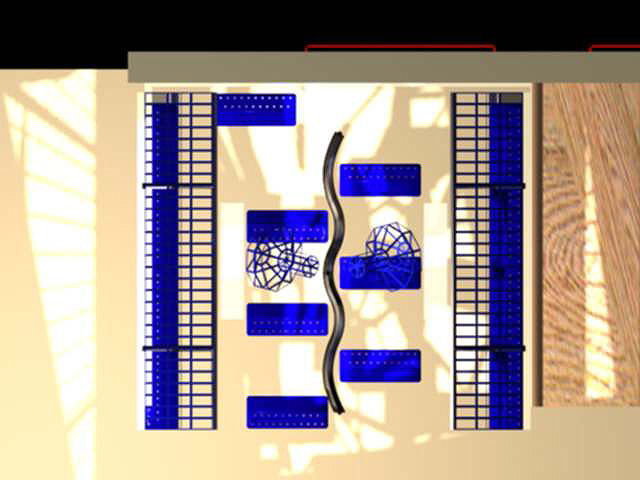

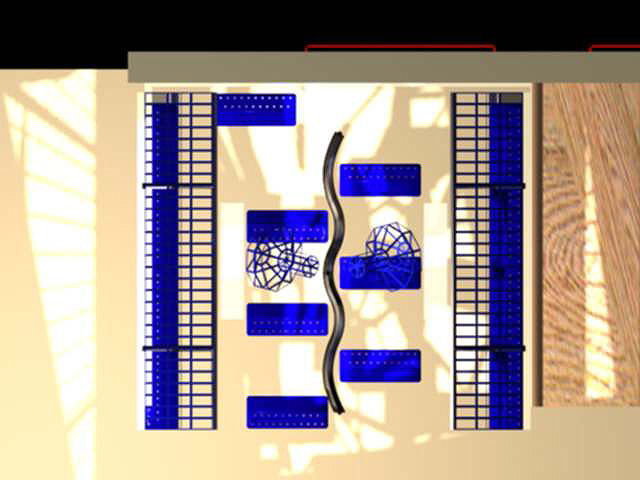

The

proposed solution is for the space between the facing pair of existing seats.

There are 15 semi standing seats proposed in this area. There are 4 seats which

are mounted against the partition on either sides. One seat is mounted on the

coach wall. There are three pairs of staggered free standing seats. The seats

are mounted at 700 mm. The width of the seats are 350 mm. The distance between

the side and the central rows of seats is 300 mm. (See the attached drawing).

There are set of supports for feet at 100 & 200 mm, side supports at 1050

mm and overhead grasps at 1800 mm. Luggage racks under the seat and overhead.

Additional fans and lights are provided for better ventilation and illumination.

Individual criteria are detailed below.

The

proposed solution is for the space between the facing pair of existing seats.

There are 15 semi standing seats proposed in this area. There are 4 seats which

are mounted against the partition on either sides. One seat is mounted on the

coach wall. There are three pairs of staggered free standing seats. The seats

are mounted at 700 mm. The width of the seats are 350 mm. The distance between

the side and the central rows of seats is 300 mm. (See the attached drawing).

There are set of supports for feet at 100 & 200 mm, side supports at 1050

mm and overhead grasps at 1800 mm. Luggage racks under the seat and overhead.

Additional fans and lights are provided for better ventilation and illumination.

Individual criteria are detailed below.

Space management

To tackle the high commuter

density efficient use of space was a prime concern. In this final solution

15 commuters can be accommodated. This space is equivalent to the space

currently occupied by the pair of facing rows of seats. All

the 15 commuters will remain at equal level of comfort.

The space between the

rows of seat is optimized for the leg room. The space is just sufficient

for a person to pass though sideways (see photograph for idea of space).

If enough space is provided for a person to pass straight then, another

commute may come and stand in between and violate the personal space of

the seated.

Ergonomics

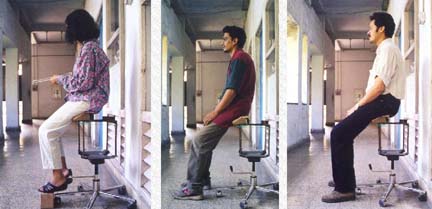

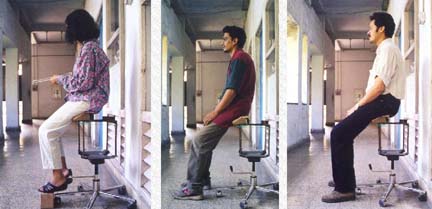

It was essential to

come up with a new set of dimensions to meet these requirements. By way

of experimentation and research the dimensions for the seats were fixed.

The height of the seat was fixed at 700 mm to suite the 50 and the 95 percentile.

Provisions for footrest were made at 100 and 200 mm from the ground primarily

for 5 percentile in the stand alone seats. The width of the seat is fixed

at 350 mm to accommodate 95 %% buttock width. The other dimension is 150

mm, divided into two halves. One half is horizontal and the other is inclined

at 30’ from horizontal to support the thighs. This angle was changed from

45 to 30 degree to avoid slipping that was observed for 5%% Indian male

in the experimentation

Simulation showing how

5, 50 and 95 percentile people adapt to the sitting height of 700 mm.

Comfort

-

Physiological Comfort

The seat is designed keeping the short

duration (1 hour or less). The concept of semi seating was introduced because

of the stated reason. The conventional seats are not eliminated from the

coach. This gives the commuters an option of choosing the type of seating

in accordance to the duration of journey. The seats are provided with circular

vents to take care of perspiration. The semi standing position is not recommended

for longer journeys. Cushioning was avoided as it is prone to vandalism

and repeated abuse may make it difficult for maintainence. However the

First class coaches can be provided with cushioning. In such case, the

material that can be used is Integral Skin P.U. Foam. These seats will

then be extruded and the top surface can have linear grooves running along

the length for ease of manufacturing. If cost becomes the deciding factor

then the conventional means of cushioning (P.U. foam or Coir) an be used

on top of the proposed seats with upholstery.

-

Support and Stability

The support system was provided keeping

in mind the flexibility of posture. The supports were in the form of

-

Footrests: The footrest for the

freestanding seats were provided at 100 and 200 level. These footrests

can be used by the commuters on these seats as well as commuters sitting

on the wall supported seats. The wall supported seats are provided with

horizontal continuous supports, under the seat, at three levels so as they

can be used with flexibility by commuters sitting on both kinds of seats

(wall mounted and free standing).

-

Side supports: Passengers sitting

at the center are provided with side supports to sleep, support, read etc.

This support is provided at 1050, i.e. at 350 above the seat height. This

will take care of the scye height for the 5%% Indian male. This support

is also repeated at the 200 level to support the feet.

-

Overhead grasp: The side seats

are provided with a continuos overhead grip to support people while they

are walking out. This support is at 1800 level, within the overhead reach

of a 5%% Indian male.

-

Overhead grip for the seated: The

wall mounted seats are provided with two pair of vertical bars on either

side for grip. These grips are primarily meant for stabilizing while the

train starts and stops. These can also be used otherwise. These grips also

have an inclined support at 15 degrees off the horizontal for a comfortable

grip. Grips in the front were avoided as they will cause hindrance to the

movement of 95%% man, if they are provided for 5%% man. Raising the height

would defeat their purpose.

Ventilation:

The success of the proposal depends

on ventilation in a major way. The existing sizes of the windows are not

at all suitable for the climate of Bombay. The proposals for better ventilation

are detailed as.

-

Additional fans are proposed (consult

drawing). The angle and position of the fans are proposed considering the

breeze cone to be of 30 degrees.

-

The height of the windows should be increased

as suggested by Yogesh Dandekar

to 1050. They windows should have a single transparent louver, as in Bombay

shutting of windows is not required in the winters.

-

Additional air ducts under the seats should

be provided as suggested in the Aerospace Department report.

Illumination:

Additional fluorescent lights are

proposed to enable the commuters to read newspapers. These luminaries will

have reflectors at the back so that the light does not interfere with the

fans and is directed to the commuters.

Psychological Comfort:

The claustrophobic feeling one generally

encounters was avoided by raising the level of the seat to 700 mm. This

facilitates the seated to come face to face to with the standees.

The seating configuration normally

does not allow commuters to sit face to face. This allows for adequate

personal space for sitting or reading (see the picture). However if commuters

are a part of the group, the commuter sitting in the center can turn at

90 degrees and interact with the other commuter.

The spacing between the

wall mounted seats and free standing seats

Luggage Space:

Luggage space was added to the usual

luggage racks. This luggage space was divided into two parts. One was the

overhead space (perpendicular to the existing luggage holds). The second

was provided under the seats (aligned with the partitions.) the latter

is primarily meant for the office bags and is smaller in size, while the

former can be used to for larger luggage.

Material & Manufacturing Considerations:

The top of the seat can be made by

cold rolled extrusion or pressing and punching operation. These may be

possible as Indian Railways have a good workshop setup. The end of the

seats are plugged with PP plugs with filleted ends to avoid injuries. For

smaller trial runs the same can be made in FRP. The vertical support is

MS tube which is fixed to the footrest unit below. The footrest unit can

be sand cast and in turn can be bolted in to the floor. The grips and other

support are MS extrusions.

The walls are prone to stickers

and graffiti . These can be coated with Silicone rubber based

release coat (similar to sticker release) over the normal coat of paint.

This will be resistant to graffiti using normal paints. The stickers can

be taken off easily form this coat. Special spaces without silicone release

can be sold as advertisement spaces to fetch extra revenue.

The

proposed solution is for the space between the facing pair of existing seats.

There are 15 semi standing seats proposed in this area. There are 4 seats which

are mounted against the partition on either sides. One seat is mounted on the

coach wall. There are three pairs of staggered free standing seats. The seats

are mounted at 700 mm. The width of the seats are 350 mm. The distance between

the side and the central rows of seats is 300 mm. (See the attached drawing).

There are set of supports for feet at 100 & 200 mm, side supports at 1050

mm and overhead grasps at 1800 mm. Luggage racks under the seat and overhead.

Additional fans and lights are provided for better ventilation and illumination.

Individual criteria are detailed below.

The

proposed solution is for the space between the facing pair of existing seats.

There are 15 semi standing seats proposed in this area. There are 4 seats which

are mounted against the partition on either sides. One seat is mounted on the

coach wall. There are three pairs of staggered free standing seats. The seats

are mounted at 700 mm. The width of the seats are 350 mm. The distance between

the side and the central rows of seats is 300 mm. (See the attached drawing).

There are set of supports for feet at 100 & 200 mm, side supports at 1050

mm and overhead grasps at 1800 mm. Luggage racks under the seat and overhead.

Additional fans and lights are provided for better ventilation and illumination.

Individual criteria are detailed below.