PROFILE

Name: Lakshmi

Narayana Y.

Designation: Design Engineer

Qualification: M.Tech

M.Tech.

Project (2003):

"STRESS AND VIBRATION STUDIES OF AN AERO-ENGINE COMPRESSOR

DISC”

Synopsis:

Compressor unit, located in the fore front

forms one of the vital systems of an aero-engine. It generally consists of two

stages: (1) Low Pressure Compressor (LPC) Unit and (2) High Pressure Compressor

(HPC) Unit each independently consisting of several stages. The first stage of

LPC is called fan assembly which consists of a set of blades mounted on a disc.

On the front side, the disc carries a bullet-nose. Being situated in the

fore-front, the fan assembly is occasionally prone to bird hit. This renders the

design of it more challenging as the assembly is required to contain the damage

and revive its performance after the impact.

The design and

development process of fan assembly consists of two phases:

(1) Aerodynamic design and (2) Mechanical

design.

1. Aerodynamic

Design: Based on the

aerodynamic performance requirements the principal disc dimensions namely bore,

rim diameters and axial widths are computed.

2.

3. Mechanical Design: The parameters considered in the

mechanical design consist of: (a) the

number of blades and their weight, (b) the blade root geometry, (c) the rotor

speed and (d) the operating temperature.

The design analysis and validation of

compressor disc includes: stress calculations, vibration studies, heat transfer

analysis, optimization and lifing. Over-speed analysis, burst speed estimations

also forms part of design validation.

The objective of the present work is to

carry out stress and vibration characteristics of a fan disc considering the

mechanical and thermal loads. The mechanical load consists of two parts:

1. Centrifugal force due to rotor speed,

and

2. Blade centrifugal forces.

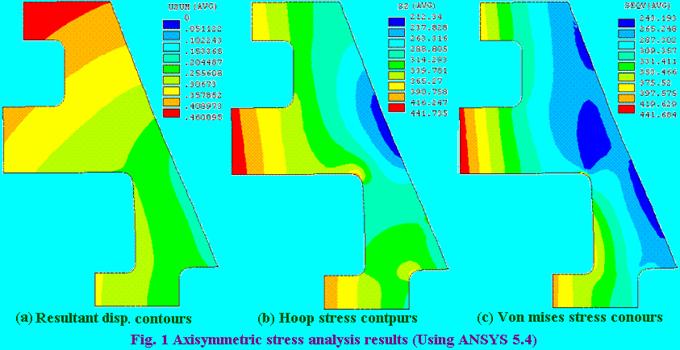

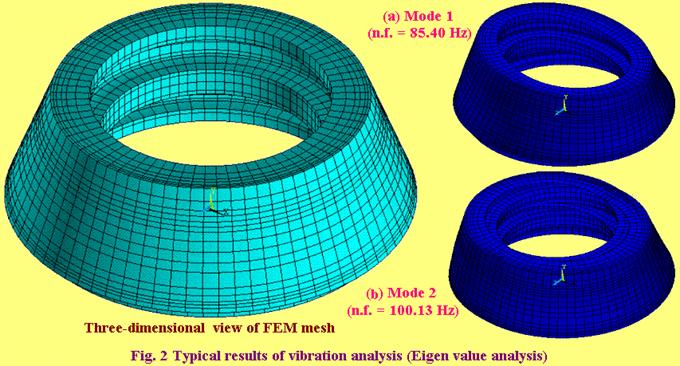

The stress and vibration analysis are carried out using

Finite Element Method. The front-end commercial software ANSYS (Ver: 5.4) [7]

is adopted in this study. The working stresses as well as stress distributions

are checked for safety on the basis of static failure considerations using Von

Mises stress theory. The vibration analysis includes the evaluation of natural

frequencies and mode shapes.

Some important results of the

research investigations:

Education:

1. M.Tech. (Machine design)

from

University, Visveswaraiah Technological

University, Belgaum.590008

2.

B.E. (Mechanical) from

NMAMIT, Nitte,

Contact Details:

Y.Lakshmi Narayana, #2988/16, 13th

A

Vijay Nagar,

E-Mail: l_narayana_y@yahoo.com

Phone : 080-23391336(R)

|Appointment

| Research Interests | Publications

| Positions Held | Academic

Experience | Students | Citations | Courses |