Bernie's Strut Tower Brace

Interior

General Powertrain

Pics Mods

Forward Motion Inc, sells strut

tower braces for Front Drive Mopars for about 140 bucks. I don't know how much

better they are than mine, but i'm quite impressed with the one I made here. I just

used some strips of 1/8th steel I found in my scrap metal bucket, a couple old bolts, and

a 1" steel bar. I bent the strips at custom angles, so they would mount flush

with the strut studs, and where the 3 strips come together.

Forward Motion Inc, sells strut

tower braces for Front Drive Mopars for about 140 bucks. I don't know how much

better they are than mine, but i'm quite impressed with the one I made here. I just

used some strips of 1/8th steel I found in my scrap metal bucket, a couple old bolts, and

a 1" steel bar. I bent the strips at custom angles, so they would mount flush

with the strut studs, and where the 3 strips come together.

I connected the strips together with a bolt going through a hole in all 3 strips.

This way, I was able to adjust the strips so they line up with the strut studs.

Once lined up, I tightened the bolt to hold the strips together so they could be

welded together and still line up with the studs.

The 1" pipe I had just happened to be 2 pieces.... one had a tapered end about

4" long, and slid inside of the other piece of 1-inch pipe. This made getting

the length of the pipe just right quite easily. But first, I connected the metal

strips to the end of the pipe. I grinded down the strips where they connected

together, so they would fit quite snugly inside the pipe. I then used a welder, and

lots of weld to attach the strips to the pipe, ensuring I had it welded at the right angle

relative to the metal strips, so the 2 pipes would meet eachother properly.

(confusing?) I completely closed the end of the pipe up with weld, with the strips

snug inside.

Then, I connected the 2 pieces of pipe together, and installed it. I

noticed that it wobbled up and down rather easily, so I installed a 4th strip between the

pipe, and the strip which is closest to the inside of the engine compartment on both ends

of the brace, and it wobbled up and down no more.

Then, I connected the 2 pieces of pipe together, and installed it. I

noticed that it wobbled up and down rather easily, so I installed a 4th strip between the

pipe, and the strip which is closest to the inside of the engine compartment on both ends

of the brace, and it wobbled up and down no more.

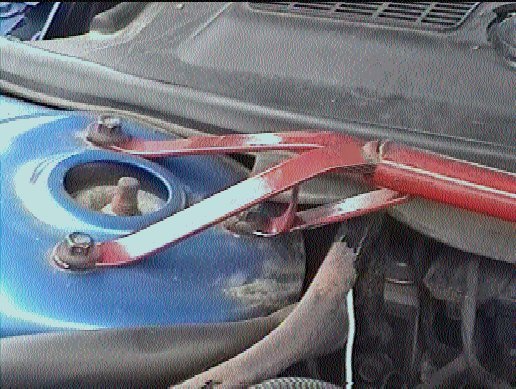

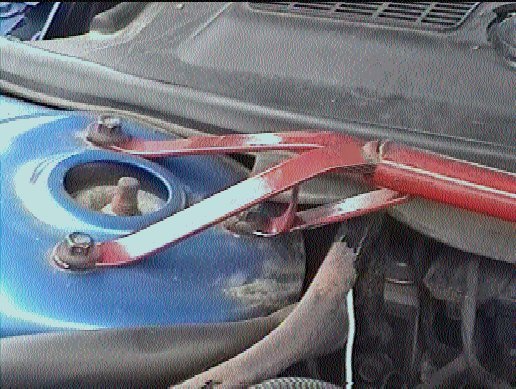

This isn't a very good quality picture, but it shows the finished

product. It clears the hood, and only touches the underhood insulation a bit.

I can even get the air filter out and remove the airbox without removing the strut

brace Surprisingly to me, it weighs less than 5 lbs, so a brace made of aluminum

wouldn't really be worth it. It is quite strong, and cannot be bent by hand while on

or off the car. I even towed the car for a short distance by the strut brace with

the garden tractor to test the strength of it. It held up perfectly.

This isn't a very good quality picture, but it shows the finished

product. It clears the hood, and only touches the underhood insulation a bit.

I can even get the air filter out and remove the airbox without removing the strut

brace Surprisingly to me, it weighs less than 5 lbs, so a brace made of aluminum

wouldn't really be worth it. It is quite strong, and cannot be bent by hand while on

or off the car. I even towed the car for a short distance by the strut brace with

the garden tractor to test the strength of it. It held up perfectly.

I have noticed an improvment in steering response, and slightly less vibrations, and a

slightly firmer ride. Some people have reported an increase in understeer as a

result of the strut tower brace, which isn't a good thing. The results will vary

from car to car because of the shocks, tires, tire pressure, car's age, weight of car,

suspension quality, and what kind of gum you're chewing and more. I've heard this

stuff from a guy who used to build race cars for a living, but it is never a hinderance,

and overall always an improvment, no matter how slight it may be. I've heard from

yet another person that under certain conditions, a car chassis can easily flex 3/4 inch

in all 3 dimensions.

I have designed a REAR wheelwell brace, which helps even more than a strut brace does

in g-bodies. I gave the idea to someone else who beat me to building one, and he

says frame flex is history, and handling is much better, and the understeer caused by the

strut tower brace is also history. I will post my results when mine is finished.

It will be easily and quickly removable, not any heavier than my strut tower brace,

and will require no welding to the frame or new holes to be drilled, and the rear seats

will remain fully functional. Stay tuned as I'll have my results up.

Forward Motion Inc, sells strut

tower braces for Front Drive Mopars for about 140 bucks. I don't know how much

better they are than mine, but i'm quite impressed with the one I made here. I just

used some strips of 1/8th steel I found in my scrap metal bucket, a couple old bolts, and

a 1" steel bar. I bent the strips at custom angles, so they would mount flush

with the strut studs, and where the 3 strips come together.

Forward Motion Inc, sells strut

tower braces for Front Drive Mopars for about 140 bucks. I don't know how much

better they are than mine, but i'm quite impressed with the one I made here. I just

used some strips of 1/8th steel I found in my scrap metal bucket, a couple old bolts, and

a 1" steel bar. I bent the strips at custom angles, so they would mount flush

with the strut studs, and where the 3 strips come together.  Then, I connected the 2 pieces of pipe together, and installed it. I

noticed that it wobbled up and down rather easily, so I installed a 4th strip between the

pipe, and the strip which is closest to the inside of the engine compartment on both ends

of the brace, and it wobbled up and down no more.

Then, I connected the 2 pieces of pipe together, and installed it. I

noticed that it wobbled up and down rather easily, so I installed a 4th strip between the

pipe, and the strip which is closest to the inside of the engine compartment on both ends

of the brace, and it wobbled up and down no more.  This isn't a very good quality picture, but it shows the finished

product. It clears the hood, and only touches the underhood insulation a bit.

I can even get the air filter out and remove the airbox without removing the strut

brace Surprisingly to me, it weighs less than 5 lbs, so a brace made of aluminum

wouldn't really be worth it. It is quite strong, and cannot be bent by hand while on

or off the car. I even towed the car for a short distance by the strut brace with

the garden tractor to test the strength of it. It held up perfectly.

This isn't a very good quality picture, but it shows the finished

product. It clears the hood, and only touches the underhood insulation a bit.

I can even get the air filter out and remove the airbox without removing the strut

brace Surprisingly to me, it weighs less than 5 lbs, so a brace made of aluminum

wouldn't really be worth it. It is quite strong, and cannot be bent by hand while on

or off the car. I even towed the car for a short distance by the strut brace with

the garden tractor to test the strength of it. It held up perfectly.