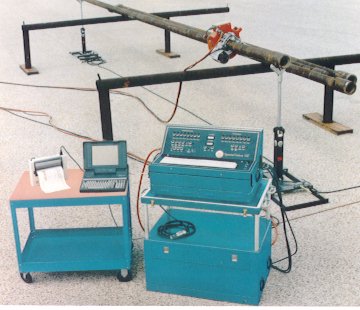

Electromagnetic Inspection (EMI) of the Drill string was pioneered by Tuboscope in the early 1950. Our latest New generation of EMI Inspection units have been designed as a culmination of almost six decades in the inspection business.

The system incorporates the

latest micro-processor technology and will detect defects that will shorten

the life of your drill pipe. The system has been proven as effective at

a well site as it is in a pipe yard.

Our EMI inspection system combines sophisticated microprocessing circuitry, enhanced search coil sensitivity and on-board interpretation aids for the ultimate in flaw detection.

We convey the EMI system along your drill pipe, magnetizing the pipe and scrutinizing its circumference with a battery of search coils to detect variations in the magnetic field, called "flux leakage." The system's expanded 16-channel electronics and sensitive microprocessor technology greatly improve its flawdefinition capability.

Our engineers recently increased the sensitivity of the EMI system's search coils. And added more of them. These improvements expanded the system's ability to zero in on transverse and three-dimensional defects, such as fatigue cracks and corrosion pits. So now this system is more precise than ever,

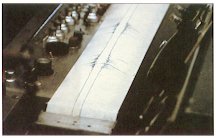

This flaw indicator panel

displays the perimeter position of each detected flaw, enhancing the system's

precision in guiding an inspector who verifies all defects.

A flaw indicator panel

enhances the EMI system's precision by displaying the perimeter position

of each detected flaw, which aids the inspector who verifies the defects

as the pipe is being inspected. Advanced signal processing allows

the operator to compensate for varying pipe conditions, minimizing

the chance of false readings.

Web

Site created and maintained by

Jayesh Bhatt at Tuboscope , Indonesia.

Copyright

© 1998 [Tuboscope]. All rights reserved.

Revised:

January 30,1998