After alot of research, I've decide to go for the following:

-A modified airfoil to reduce/eliminate flutter.

-Ailerons tapered back 45 degrees, to

eliminate breakage.

-Aileron controls modified for kevlar Pull-Pull operation.

-Carbon fiber reinforced center section.

-Servos mounted higher, for easy control arm access.

-No wing tip skids, they break too often.

-Dual strut landing

gear, instead of single, speaks for itself - nicer landings.

-Antenna tube will be routed through wing for easy install.

-Continuous wing covering, seamless hinge-line so oil will be less likely to soak in..

-Kevlar Tail wires to almost

eliminate rudder breakage.

-Double beveled TE and surface LE, for very solid, slop free controls

The ball bearing OS 32F and the bushing 40FP weigh exactly the same. The 32F is a good engine,

but the 40FP with a Mousse Can Pipe is just as good for sport flying. For hovering, I prefer the 40FP w/MCP because of it's

EXCELLENT throttle response at all throttle settings. Engine choice is tough!

The idea behind the Stickit type planes is to keep them as light as possible, which allows them

to be EXTREMELY maneuverable, while flying at fairly slow speeds. To do this, you need to use an engine that weighs about

9 ounces, yet produces good power. The MCP helps here by increasing the power, reducing the weight over the stock muffler,

and further reducing the effective nose weight by shifting the weight of the muffler towards the rear of the plane. About

90% of sport flying is done at partial throttle, which means that the engine must run consistently at ALL throttle settings.

IMHO, the OS 40FP is one of the best choices for sport flying because of it's 8.75 ounce weight, it's decent power for it's

weight, and it's EXCELLENT throttling.....especially with a MCP.

The main wing spars are supposed to extend beyond the root rib about 1/4 inch. Then when

the wing panels are mounted to the boom assembly, the ends of the spars will fit into the notches in the motor mount pod,

trapping the motor mount pod between them. The notches in the motor mount pod also accept the one piece spar doublers that

keep the wing panels from pulling away from the boom.

Now for the pics!

Here is the design for the modified airfoil I used. This will decrease flutter.

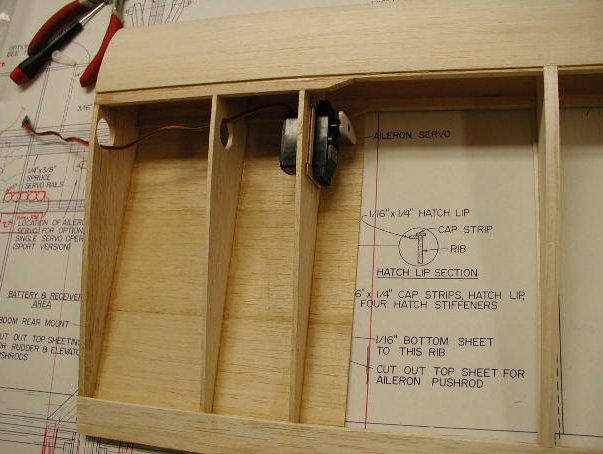

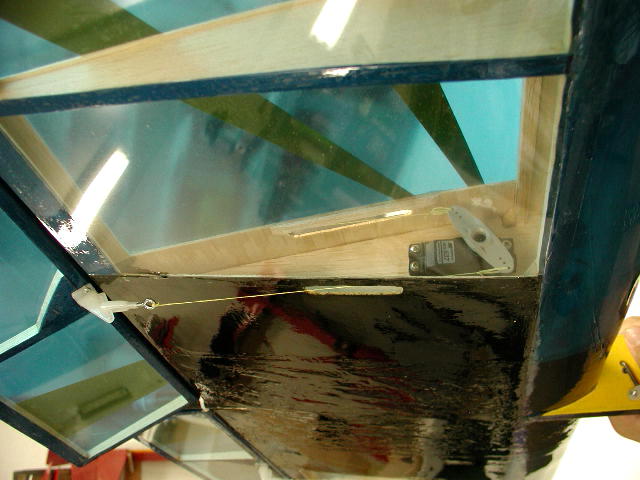

Finished wing halves look like this. See the pull pull servo placement. Ready to join winghalves at this point.

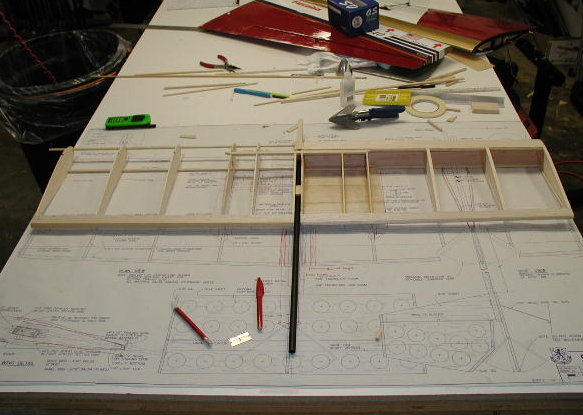

Joining the winghalves now. Use slow epoxy if you want extra strength, I used 40 minute finish set 'poxy.

Here is the engine pod laminate. I used carbon veil and 3 layers of 1/8" balsa, and 1 layer of 1/16" to get the right

thickness. Its very light!

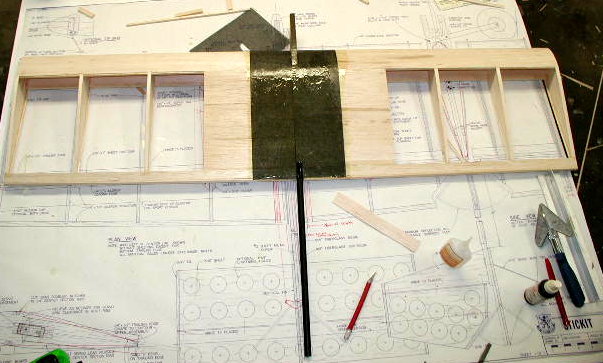

Wings are joined, engine pod is in place. I'm ready to complete the wing sheeting, and start working on the tail.

Here the wing is completely sheeted, and I laminated some carbon veil in the center to give added rigidity in the area,

seeing as I used lighter balsa in the build.

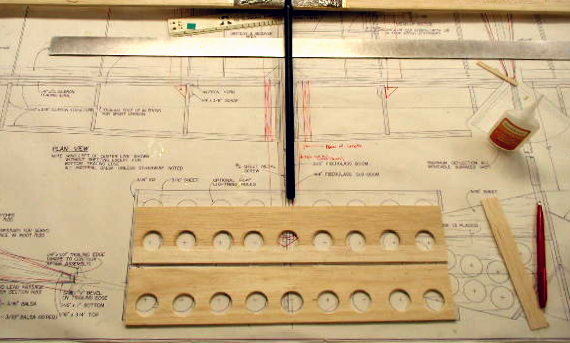

Starting the tail construction... Lots of lightning holes, I'm using medium/heavy balsa on this to help with the strength...

Here is what the finished wing/aileron/servo/control looks like. I used clear monokote to give it sort of a "cool" factor,

and to help you see the build details.

Here is the plane fully covered and assembled, less the engine, which is TBD. I decided to go with a homemade dual landing

gear, I didnt like the idea of the single "pod".

|