Non-Destructive

Testing

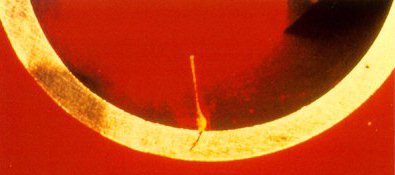

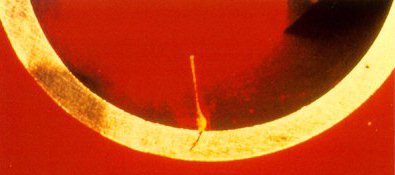

Flaws or Defects , whether

obvious or nearly invisible to the

naked eye are often found in new

tubular goods as they roll off the

manufacturing line. While flaws and defects are

nor necessarily deterimental to your tubular

servicability, high downhole stresses and corrosion

can quickly turn them into failures.

Some

common defects that a new tubular inspection

program can detect include mill slugs , pits

, seams , overlaps , gouges , mashes and dents. Any of

these defects can seriously impair the

performance of your tubular goods.

Some

common defects that a new tubular inspection

program can detect include mill slugs , pits

, seams , overlaps , gouges , mashes and dents. Any of

these defects can seriously impair the

performance of your tubular goods.

A

new tubular inspection program from Tuboscope

, Indonesia identifies these types of defects

before the tubulars go into service. So

you minimize your risk before they

negatively impact your operation.

A

new tubular inspection program from Tuboscope

, Indonesia identifies these types of defects

before the tubulars go into service. So

you minimize your risk before they

negatively impact your operation.

For production tubing , our

inspection programs help establish a benchmark

against whcih future inspections can be

measured. Because once the integrity of your

tubulars have been initially established, future

inspection only need check for service

induced defects. This is especially important

if you pool tubulars from a wide

range of wells under substantially different

operating or production conditions.

This isn't just effective

materials management , it's cost-effective risk

management.

The following is a

partial list of our new tube

body inspection services offered in Indonesia.

Pipe

Body

Ultrasonic Weld Line

Inspection

End

Area and Thread Inspection

Clean and Visual Thread

Inspection

Ring and Plug gauging

Related

Services

Full Length Magnetic

Particle Inspection

Used Tubing and Casing

Inspection services can prolong tubing life

, reduce production costs and help avoid

workovers. To find out more about our

used Casing and Tubing Inspection program

in Indonesia click here.

Web

Site created and maintained by

Jayesh Bhatt at Tuboscope , Indonesia.

Copyright

© 1998 [Tuboscope]. All rights reserved.

Revised:

January 01,1998

Some

common defects that a new tubular inspection

program can detect include mill slugs , pits

, seams , overlaps , gouges , mashes and dents. Any of

these defects can seriously impair the

performance of your tubular goods.

Some

common defects that a new tubular inspection

program can detect include mill slugs , pits

, seams , overlaps , gouges , mashes and dents. Any of

these defects can seriously impair the

performance of your tubular goods.

A

new tubular inspection program from Tuboscope

, Indonesia identifies these types of defects

before the tubulars go into service. So

you minimize your risk before they

negatively impact your operation.

A

new tubular inspection program from Tuboscope

, Indonesia identifies these types of defects

before the tubulars go into service. So

you minimize your risk before they

negatively impact your operation.